Aston Martin has revealed a range of new, factory-certified components for its DB4, DB5, DB6 and certain V8 models from the 1960s and 1970s.

They’re available through its Aston Martin Works division, which is responsible for servicing of modern vehicles as well as heritage servicing and restoration.

The company has developed brand new engine blocks, cylinder heads, gearboxes and other major components for selected vintage Aston Martin models.

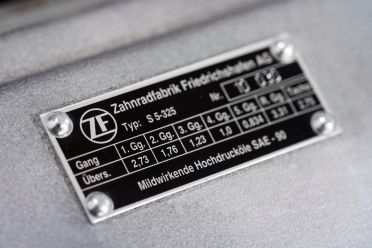

The need for new parts stemmed from Aston Martin’s continuation program which has required re-manufacturing of certain components including gearboxes.

“Working with the exceptional engineers both here and at Aston Martin’s Gaydon headquarters, key parts suppliers were tasked with developing these new components,” said Paul Spires, president of Aston Martin Works.

“The heritage department at gearbox supplier ZF, for instance, was invaluable in helping to recreate original specification gearboxes – making these parts available for the first time since the early 1970s.”

All parts will be supplied with certified documentation to confirm the components have been checked and approved by the Aston Martin Works team.

Aston Martin is not the first brand to re-manufacture parts for its historic line-up, with Porsche, Mazda and Nissan among the car companies that have done the same.

In late 2020, Mazda announced it will reproduce parts for its FC- and FD-series RX-7.

Around the same time Nismo, Nissan’s motorsports and tuning arm, began manufacturing parts for the R32 Skyline GT-R.

More recently Porsche has begun re-manufacturing parts such as new crankcases, in addition to developing new infotainment systems with Apple CarPlay for its historic models.