Tesla didn’t end up showing any of its next-generation vehicles at its 2023 Investor Day, but it did detail how they will be built.

The next-generation vehicles are expected to include a vehicle to slot in under the Model 3, while a robotaxi version has been confirmed.

In a Q&A session, when Tesla CEO Elon Musk was asked when the next-generation vehicles will be previewed, what shape they would take, and where else they could be produced, the outspoken company boss said, “We’re going to have to decline to answer”.

He indicated there would be a “proper sort of product event” for the vehicles, and also underscored the company’s push for more affordable vehicles.

The company’s vice president of vehicle engineering, Lars Moravy, shed some light in the session even if his boss didn’t.

“Elon alluded to the fact that Mexico will build our next-gen vehicle, but we will also be doing that in our other plants,” said Mr Moravy.

“And so it’s really about getting them all up and running. We expect that to be a huge volume product, and we’re gonna move that quickly over the next couple of years.

“Our next generation platform is more than one segment and it’s really worth thinking about all the segments that are available that we haven’t captured and where the market would be, in designing it with our supply chain partners so that we can go quickly through those segments for where we need.

“If you make a car desirable, and affordable. You know, oftentimes it doesn’t necessarily matter what segment it’s in, because it’s one that you bought.”

Mr Moravy pointed out the Model 3 has proved enormously successful, defying commentators who thought its sedan body style would hinder it.

The new Mexican plant, to be built in the northern state of Nuevo Leon, will be supplemental to Tesla’s overall production, with the company planning to increase output at all of its other plants.

While details on what shape the next-generation vehicles will take weren’t forthcoming, the company did detail the new production process that could cut costs by up to 50 per cent.

“Cost reductions don’t come from any one place… We have to go through everything,” said chief financial officer Zachary Kirkhorn.

The company said further cost savings will be found in the robotaxi version of the next-gen model.

Tesla says it already took out 50 per cent of costs from its Model S and Model X to its Model 3 and Model Y, and wants to do it again.

It says past Tesla vehicles were designed first, then engineered, then manufactured. But with the next-generation model, it wants to bring the design, engineering and manufacturing teams together at the beginning.

The company pointed out the inefficiencies of the traditional way of manufacturing a vehicle, saying it’s at “the tail end of its manufacturing optimisation” just over 100 years since Henry Ford opened his first assembly line.

In particular, Mr Moravy cited how the doors are attached to the vehicle and painted before being removed again, though Tesla design head Franz von Holzhausen crowed about Toyota executives calling the Model Y a “work of art”, citing this Automotive News report.

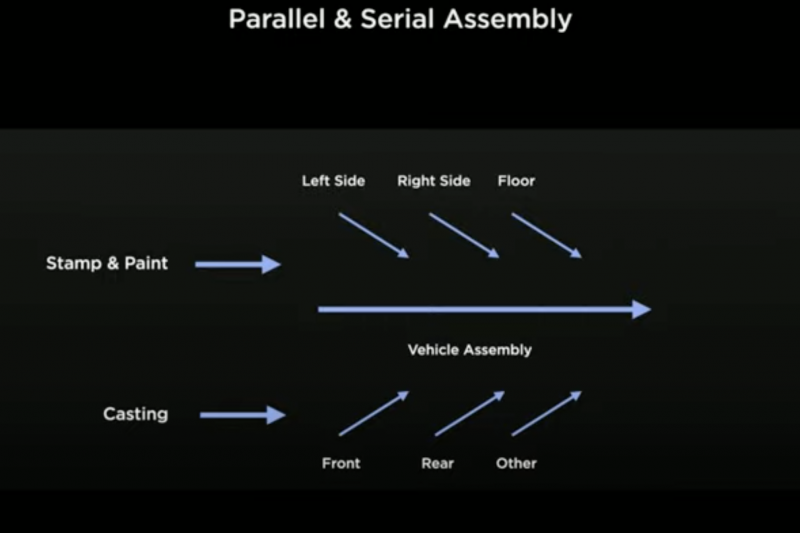

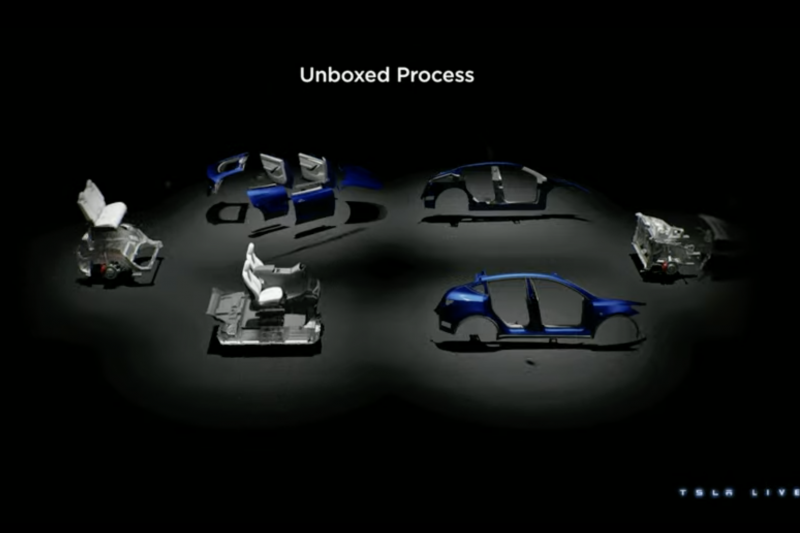

The solution involves having more people working simultaneously on smaller parts of the vehicle, for claimed operator density and space time efficiency improvements of 44 per cent and 30 per cent, respectively.

This will improve with further automation on the production line.

“We [will] only do things that are necessary, with a much shorter final line blocking a lot less of the rest of the factory,” said Mr Moravy.

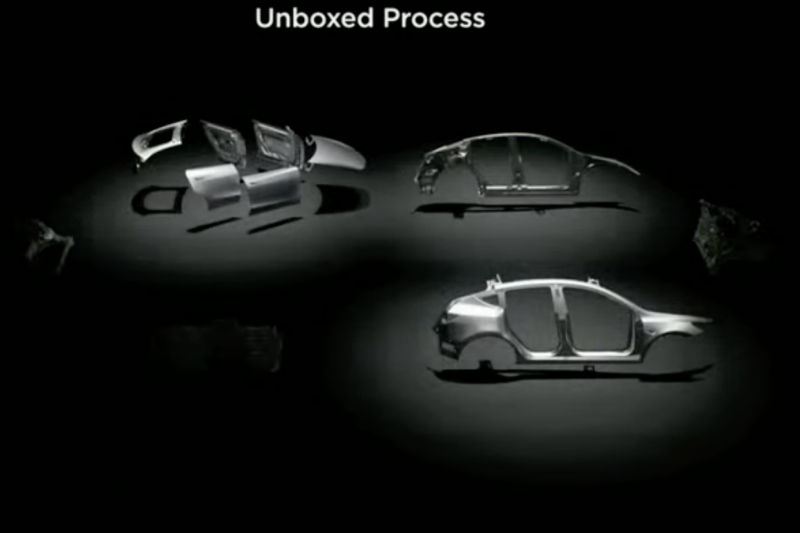

“We [will] build all the sides of the car independently, only paint what we need to, and then we assemble all the parts of the car once and only once.”

“It means we’re doing more work on the car more of the time,” Mr Moravy added, noting there will be fewer slow, inefficient movements of heavy machinery.

The interior would be attached from the top down or bottom up, and the doors would be added at the end – not attached, detached and attached again.

Tesla says these new production methods aren’t likely to be employed on current vehicles as it would necessitate extensive factory retooling, so you can ignore the use of a Model Y in these diagrams.