Due to the Coronavirus pandemic, desperately-needed ventilators are in short supply, while some hospitals are also grappling with shortages of personal protective equipment.

Fortunately, some automakers have stepped up to help.

Fiat Chrysler (FCA), Ford, General Motors, McLaren, and Nissan have all agreed to use of their resources and help produce critical medical equipment, with some companies even planning to use idled factories to manufacture items.

Ford is working with GE Healthcare to expand ventilator production, and could start production in one of its factories.

Ventilators are designed to help patients struggling to breathe, and are critical as COVID-19 can cause serious respiratory failure. A shortage of ventilators can be the difference between life and death in hospitals overrun with sick patients.

Also essential in hospitals throughout are respirators, a type of personal protective equipment that safeguards workers against contaminated air.

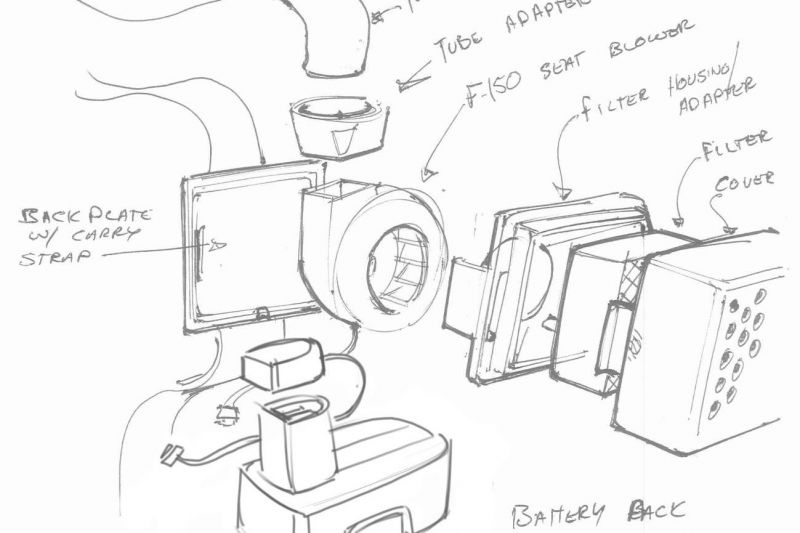

Ford is working alongside 3M to see if it can produce Powered Air-Purifying Respirators (PAPRs) at one of its plants, and the two companies are developing a new respirator design using parts such as fans from the Ford F-150’s cooled seats and 3M’s HEPA air filters.

Ford will manufacture more than 100,000 plastic face shields per week at one of its American factories and use its 3D printing capability to manufacture components for personal protective equipment.

Fellow American automaker General Motors has announced it’s partnering with Ventec Life Systems to help increase production of ventilators.

The medical device company will leverage GM’s logistics, purchasing, and manufacturing expertise.

That won’t be the end of their partnership, as The General will partner with Ventec to manufacture ventilator units at one of its factories in Indiana.

GM will re-deploy 1000 workers to its Kokomo, Indiana plant, which usually produces small electronic components for cars.

The company will produce 10,000 ventilators each month, though GM says this number could be increased. Production is set to begin in April.

As soon as next week, GM will also begin production of surgical masks at its Warren, Michigan plant. Within two weeks, the company expects to produce 50,000 units per day, eventually increasing to 100,000 units per day.

Reuters reports Fiat Chrysler Automobiles and Ferrari are also looking to help with ventilator manufacturing.

The two companies are in talks with Italy’s largest ventilator manufacturer, Siare Engineering.

Italy has become the epicentre of COVID-19 the pandemic, with over 6000 deaths at the time of publish.

The two automakers would either manufacture ventilators in one of their factories in Italy, or help Siare Engineering increase its production.

A source told Reuters Ferrari could potentially manufacture equipment at its Maranello headquarters.

According to The New York Times, FCA will also use one of its Chinese factories to manufacture face shields with a production target of one million units per month.

The switch from car manufacturing to the production of medical equipment hasn’t been seen on this scale since World War II, when automakers throughout the world suspended production of cars and switched to manufacturing equipment and vehicles for the military.

McLaren is also lending its expertise in developing new ventilators, according to Automotive News Europe, though it won’t be manufacturing the equipment itself.

Nissan has also been asked by the UK government to lend its manufacturing expertise to help boost production of ventilators.

Other companies are supporting the effort in different ways.

Though his company hasn’t started producing the equipment and he initially questioned the severity of the pandemic, Tesla founder Elon Musk announced on Twitter he’d purchased 1255 ResMed, Philips, and MedTronic ventilators and shipped them to the USA from China.

Most will be used in California hospitals.

It’s likely more car companies will offer their support during this crisis, whether they’re providing their expertise or retooling their factories to assemble equipment in-house.