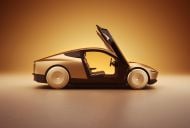

The first production 2022 BMW i4 electric liftback has just rolled off the line in Munich, Germany.

Due to arrive Down Under in the first quarter of 2022, the i4 is being built alongside the internal-combustion and plug-in hybrid BMW 3 Series range, as well as the M3 and 4 Series Gran Coupe.

In order to begin production of this all-electric model, BMW had to make some changes to its almost 100-year-old Munich production plant.

Around 90 per cent of the existing production system in the Munich body shop could be used to produce the i4 according to BMW.

Some additional manufacturing systems were required for the floor and rear end assembly.

A challenge for BMW was the integration of the high-voltage battery components into the platform of the i4.

The process that BMW decided to go with was to install these components on a fully-automated battery assembly system that works from below the vehicle.

By using high-resolution cameras, the underbody of the i4 is thoroughly scanned to make sure the surface is clean and there are no impurities before the battery installation begins.

This process isn’t revolutionary in the electric vehicle (EV) production realm, with the battery pack in the Nissan Ariya electric SUV being installed in a similar way.

The plans to upgrade the Munich plant were made less than a year ago with new vehicle assembly and bodyshop facilities constructed, as well as a relocation of engine production.

The cost for all of these alterations to the Munich plant for the i4 came in at a total of €200 million (A$311.72 million).

Among all of these changes to the production plant, BMW is also 3D-scanning the entire Munich plant in detail to have a digital version of both the building and its systems.

Several production plants have already been scanned according to BMW, including the Spartanburg and Regensburg plants, with the Dingolfing plant currently getting scanned.

With the introduction of this all-electric model to the BMW range, the company says that the Munich plant is on its way to going fully electric with fewer emissions.

“By 2023 more than half of all vehicles from our Munich facility will have an electrified drive,” says Milan Nedeljkovic, BMW AG Board Member for Production.

“The majority will be fully electric. So Munich goes fully electric.”

BMW has also announced that the local emissions from transport logistics at its Munich plant will “gradually fall to zero”.

Currently there are more than 750 truck deliveries needed every day for the plant to function with parts brought in.

BMW aims to reduce its emissions by making better use of rail transports as well as battery-electric trucks.

Its ultimate goal is to eliminate emissions completely from transport logistics in the Munich area, but also make significant cuts within a broader radius and in its intercontinental transport.

The i4 is a precursor to the EVs that are going to be built on the dedicated electric Neue Klasse platform that’ll enter production in the middle of this decade.

With the exception of the ageing i3, all electric BMW models, including the i4, are based on internal-combustion engine platforms.

Two different i4 variants will be available at launch: the eDrive40 and M50, priced at $99,990 and $124,900 before on-road costs, respectively.

Between 510 and 590 kilometres of WLTP-certified range will be offered depending on the variant, with both versions featuring an 84kWh battery that allows for DC fast-charging at up to 200kW.

The i4 will launch with the new BMW Operating System 8 infotainment system featuring a “curved dash” like the one seen in the iX all-electric SUV.

Both variants will also come with a complimentary five-year subscription to fast DC and ultra-rapid chargers on the ChargeFox network.