James Wong

3 Days Ago

How is 3D printing changing the game? Let's look at the role of additive manufacturing in the design, development and production of automobiles.

Design Contributor

Design Contributor

What once was considered a sci-fi technology is evolving to become an integral part of car production, with a greater spectrum of use than we initially imagined.

3D printers – the electronic devices with the ability to print three-dimensional objects layer by layer – aren’t something new. Τhe theoretical base for the technology was introduced in the ‘70s, with the first applications in the ‘80s.

Initially, the process was time consuming and the materials that could be printed were not known for their durability and rigidity, limiting the possible applications of this technology.

However, the ease with which three-dimensional objects can be transferred from the computer to the real world got the attention of large companies, which gradually embraced the technology that has given rise to rapid prototyping.

The automotive industry was one of the first adopters of 3D printing in the design and development of concept cars.

Early 3D printers made it possible for designers and engineers to create different variations of components, testing their durability, aerodynamics, ergonomics and styling. This approach saved a lot of time and money, especially when you compare it with other time-consuming and expensive production methods.

Furthermore, unlike moulding, 3D printing doesn’t have restrictions on the shape of the object, allowing great freedom to the designers and engineers, resulting in significant weight savings.

Over the years, the evolution of the technology has made it possible to print objects using a wide variety of materials including ABS plastic, nylon, epoxy resins, wax, silver, titanium, steel, photopolymers, polycarbonate, ceramics and carbon fibre.

This meant that 3D printers were no longer limited to developing prototypes, as they became technically suited and economically viable for mass production, adopting the term additive manufacturing.

The first car with a body entirely made by a 3D printer was the Urbee (2010), an aerodynamic three-wheel prototype with a fully enclosed body designed by engineer Jim Kor.

In 2014, Christian von Koenigsegg announced his company would use 3D printing in the limited production of the Koenisgegg One:1 hypercar (2014-2016).

For the first time ever, 3D printers were used for mechanical components in a production car, including the variable turbo of the 1000 kW 5.0-litre V8 engine and magnesium exhaust pipes.

A company that quickly embraced 3D Printing was Local Motors from Arizona, US. Its Strati concept was entirely made in a 3D printer, apart from the electric motor, the battery, and the wiring.

It took 44 hours for the production and assembly of a working prototype by two people, a computer, and a 3D Printer.

The next step was the Local Motors Oli, a 3D printed autonomous van that is still under development with plans for small scale production.

Rimac Automobili from Croatia, which has quickly evolved from a small scale hypercar manufacturer to a major supplier of electric propulsions systems to several established automakers, has been using 3D Printers for the R&D of the fully electric hypercar C_Two that is currently in the final stages of development.

A great example of how 3D printing can accelerate the design and development of a production car is the Ford Mustang Shelby GT500.

Ford used rapid prototyping in the design of the aerodynamic kit for maximum downforce and various cooling parts enhancing thermal management. Further, the production model uses 3D-printed brake pad components created at Ford’s Advanced Manufacturing Centre in Redford, Michigan.

Speaking of brakes, Bugatti in 2018 presented the first 3D-printed eight-piston monobloc brake caliper made of titanium, which is also the largest in the automotive industry.

Besides the obvious cool factor, its design makes it 40 per cent lighter than a conventional aluminium caliper and still strong enough to withstand enormous stress under heavy braking.

Bugatti is also using 3D printing for the titanium exhaust covers used on limited-production models like the Chiron Sport, Chiron Super Sport 300+, Chiron Pur Sport, Divo, La Voiture Noire, and Centodieci, with weight-saving advantages.

Another company currently sitting at the forefront of 3D printing is Porsche. In 2018, the manufacturer from Stuttgart offered a range of around 20 reproduced 3D-printed parts made of plastic, titanium or aluminium alloy for its classic models.

Those parts – like a release lever for the clutch of the 959 – were out of stock and in demand from classic car owners. Their reproduction in such small numbers wouldn’t be viable if it weren’t for additive manufacturing, as the necessary equipment was seriously damaged or destroyed.

In May 2020, Porsche offered 3D printed bodyform full-bucket seats for the 911 and 718 ranges. Those personalised backrest cushions are made of expanded polypropylene bonded to a breathable comfort layer from polyurethane-based materials and perforated outer skin (Racetex).

The project started with seat prototypes for track use only, however starting from 2021 they will be available as a street-legal option, and customers will be able to choose between three firmness levels and many different colours.

Porsche is also using a 3D printer for the production of the pistons used in the engine of the 911 GT2 RS.

As Porsche describes, “the pistons were manufactured from high-purity metal powder using the laser metal fusion process”.

This allowed for 10 per cent less weight compared to conventional forged pistons, and also the integration of a closed cooling duct inside the piston crown that wouldn’t be possible with the traditional production methods.

Thanks to additive manufacturing, engineers at Zuffenhausen were able to increase engine speed, lower the temperature load and optimise combustion, extracting an additional 22kW of power from the already immensely powerful 515kW twin-turbo boxer engine.

On the other side of the Atlantic, the Los Angeles-based Czinger is 3D printing parts as a contractor for other automakers, but also for its first production car – the hybrid hypercar Czinger 21C.

Most of the vehicle’s components are manufactured by cutting-edge 3D printers developed in-house, including parts of the chassis, suspension, body and cabin.

Those parts are made from aluminium, titanium, carbon fibre, and other materials. The key here is the ability to 3D print in large numbers for mass production, as Kevin Czinger, the company’s founder and CEO suggests.

Among the earliest adopters of 3D printing was BMW, which started using the technology as early as 1991. Fast forward to 2019, BMW’s annual production of 3D printed parts exceeded the 300,000 mark.

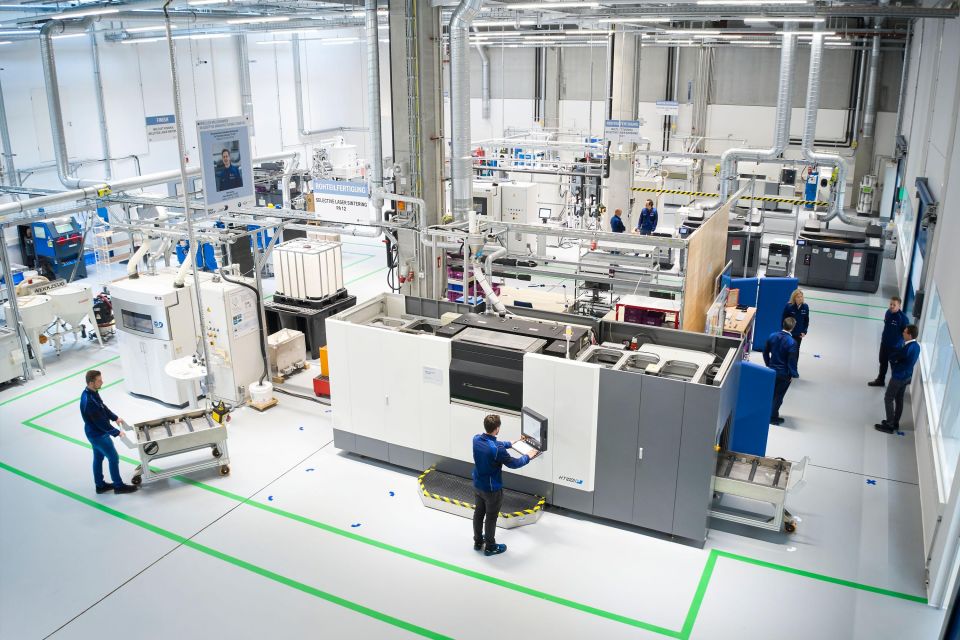

In 2020, after a €15 million investment, BMW Group opened a brand new additive manufacturing campus in Munich, Germany, with the goal of accelerating vehicle development and shortening production times for future models.

The new facility houses half of BMW’s global strength of 100 specialised 3D printers working with metal and different kinds of plastics, and currently employs 80 people.

Volkswagen Group has also been using additive manufacturing since the late ’90s, and is also investing heavily on the technology with each sub-brand utilising its own 3D printers – Audi (Ingolstadt), Bentley (Crewe), SEAT (Barcelona), Skoda (Prague), the aforementioned Bugatti (Molsheim) and Porsche (Stuttgart), and of course Volkswagen’s main facility (Wolfsburg).

The German brand is already performing crash tests on platforms with 3D printed parts, and plans to put them in production starting from 2023. Volkswagen also 3D prints all of the tools, jigs, and fixtures used in the factories saving 91 per cent in development costs and reducing development time by 95 per cent.

In the near future, Volkswagen is planning to offer a range of 3D printed car parts such as personalised gear knobs, key fobs, or tailgate lettering, using HP’s Metal Jet technology. The goal is to print 50,000 to 100,000 parts on a yearly basis.

Some other notable examples of 3D printed parts are bodykits for the Daihatsu Copen (2016), the dashboard trim and other bits and pieces for the Mini Cooper (2018) and the full range of accessories for the Fiat Centoventi concept (2019).

3D printing has proven it’s here to stay, and its use in the automotive industry will continue to grow exponentially over the next few years. Besides design and development of prototypes, automakers are moving towards the use of additive manufacturing as an integral part of car production, large or small scale.

This technology is also expected to make a big change in car customization, allowing designers to create more variations of exterior and interior parts, and users to further personalise their vehicles according to their taste.

The fact 3D printers are becoming more affordable and accessible for the general public opens up new possibilities for the commercial use of this technology.

It’s possible in the future, every user could buy and download – or even create – the CAD files of any product including car parts, 3D print them at home and place them on his/her own car.

Last but not least, the ability of 3D printers to create complex shapes combining different materials in one object could signal a new revolution – even though it is still in an early phase.

Mixed-material additive manufacturing could allow even more efficient designs, by significantly reducing the number of components needed for a specific function and minimising development and production times.

James Wong

3 Days Ago

Andrew Maclean

2 Days Ago

Max Davies

2 Days Ago

Max Davies

1 Day Ago

Josh Nevett

1 Day Ago

Damion Smy

17 Hours Ago