An Australian startup is developing a proprietary Active Wheel Alignment System (AWAS) for application on mass-market road cars, which it bills as a world-first.

The system, designed to be quickly integrated into existing suspension configurations and ECUs, can change the camber, caster, and toe of each wheel on-the-fly to both increase the amount of tyre touching the road, and reduce the highway rolling resistance responsible for extra fuel use.

It reminds one of this Dual-Axis system developed by the Mercedes-AMG F1 team.

The company is called Doftek, and after conducting R&D is now at the stage of engaging ‘tier 1’ suppliers to produce its component set for use by the global car brands that they supply, for fitment at the factory. Aftermarket applications are also being explored.

The system was invented by engineer Geoff Rogers, a car enthusiast who previously co-founded a company responsible for making a 0.36mm diameter, robotically steerable guidewire for use in certain heart and brain surgeries. Quite a career change!

Doftek claims the key to its system’s intended success is the ability to be installed in existing MacPherson strut/multi-link/double-wishbone suspension layouts, its manageable unit cost that’s intended to be on par with a magnetic suspension system, and its minimal impact on vehicle weight – about 1kg of extra sprung mass per wheel.

The system uses a bespoke ECU that can be integrated into existing software, new tie rods, and electromechanical moving strut tops that facilitate the wheel movement. It all runs on a 12V power, though the more advanced future applications will likely be embedded with 48V systems.

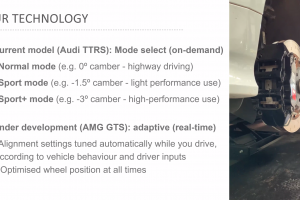

Version one of the AWAS is installed on the front wheels of an Audi TT RS, and is linked up to a selector switch offering Normal, Sport and Sport+ modes with corresponding 0-degree, -1.5-degree and -3-degree camber.

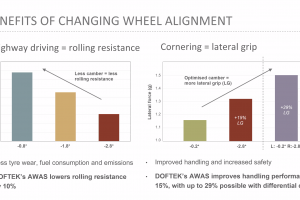

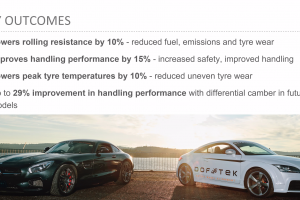

Doftek’s testing shows that the system can provide at least a 15 per cent increase in handling performance, a 10 per cent reduction in rolling resistance, and a 10 per cent reduction in peak tyre temperatures.

It’s working on a more advanced second version that can change the wheel camber etc all by itself in real-time to best suit a given moment, using sensor input data from the test car’s hardware and software.

The test car for this is a Mercedes-AMG GT S, and early indications show a 29 per cent improvement in handling performance with “differential camber”, meaning the right wheel at -2.8 degrees and the left at -0.2 degrees.

Right now the systems are not ‘closed loop’ at the wheel, meaning you still need to get normal wheel alignment done when your car is serviced. But Doftek says it is looking at adding wheel position tracking, to actually perform the wheel alignment for you.

The initial targets for AWAS are luxury and performance vehicles where costs can more easily be absorbed, followed by electric vehicles (for extended battery life) and driverless cars (for novel steering solutions) such as automatic toe-in as a brake-system redundancy add-on.

Doftek wants to have auto OEMs test a prototype unit fitted to their vehicles “once business conditions improve” post-COVID.

The prototype was co-funded by the Advanced Manufacturing Growth Centre, an agency paid for by the Australian Federal Government. Doftek and AMGC will contribute matched funding of $196,425 each to the program.

Doftek’s project partners include On Point Engineering “to contribute knowledge gained through years in the Supercars Australia” series, Erntek to supply and commission electric motors, Flexicut Engineering to manufacture purpose-built parts, and 3D Systems to rapid prototype parts and contribute 3D printing know-how.

“Our real-world testing demonstrates that this technology can provide next-generation performance gains to vehicle manufacturers. The funding and assistance provided by the AMGC has allowed us to accelerate our development and commercialisation efforts into global markets, including Europe and Japan,” said co-founder Geoff Rogers.

Co-founder of Doftek Priscilla Rogers added; “AMGC has an executive team and staff, who have the industry-specific experience, networks and thought leadership needed to be successful in bringing new technologies to market. We feel extremely fortunate to be able to work alongside an exceptional team at the AMGC, and build a strong partnership”.

Managing Director of AMGC, Jens Goennemann, called Doftek “evidence of the impact Australia’s automotive component sector can have on a global scale”.

“Doftek is proof that Australia has a strong and innovative automotive component sector exporting hundreds and thousands of components yearly for inclusion into global supply chains,” he added.

“Doftek has designed, engineered, tested and, with our assistance, will now commercialise an innovative automotive solution with global relevance and impact. In the fullness of time, Doftek expects to support 40 highly-skilled Australian manufacturing jobs.”