Andrew Maclean

5 Days Ago

Bosch's latest investment into making drastically-needed semiconductors demonstrates why shortages take so long to rectify.

Leading Tier 1 supplier Bosch has, as a byproduct, demonstrated one reason why the semiconductor shortage crippling the car industry is taking so long to rectify.

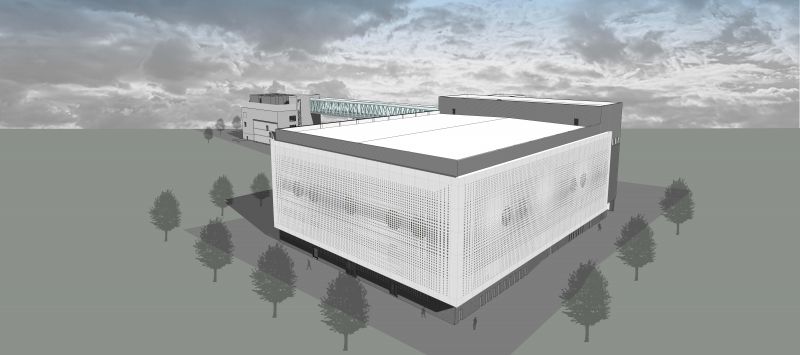

The company this week announced an additional 250 million euro ($390m) investment into a planned 3600 square-metres of clean-room chip production facilities at its Reutlingen site.

This comes on top of 400 million euros committed to similar projects in Germany and Malaysia last October.

“This investment will benefit our customers and help combat the crisis in the semiconductor supply chain,” said Bosch chairman Stefan Hartung, referring to the latest funding.

However, the kicker is the new production area to be funded by said extra 250 million euros isn’t scheduled to go into operation until 2025 – which means critical supplies of extra chips are still years away from entering the worldwide parts ecosystem.

This also clearly shows that securing greater supply of chips is not as simple as just building new factories and churning them out in no-time flat – something for which there’s enormous demand. Bosch has every incentive to do just this, if it could.

All in all, clean-room space in Reutlingen is set to grow from around 35,000 square metres at present to over 44,000 square metres by 2025.

Making these clean spaces is a very time-consuming and complex process. In the cleanrooms of chip makers’ fabs (fabrication sites), the air quality and temperature are kept controlled as robots transport wafers from machine to machine.

Bosch says it has been developing and manufacturing semiconductors for over 60 years, and for more than 50 of those years in Reutlingen – both for automotive applications and for the consumer electronics market (the latter of which bit into auto OEM supply during COVID).

Bosch-manufactured semiconductor components include application-specific integrated circuits (ASICs), microelectromechanical systems (MEMS sensors), and power semiconductors.

The further expansion of the Reutlingen site will primarily serve the growing demand for MEMS in the automotive and consumer sectors and for silicon-carbide power semiconductors. Chips made of this material are destined to play an increasing role in electro-mobility.

MORE: Staggering impact of semiconductor shortage on car industry revealed

Andrew Maclean

5 Days Ago

Josh Nevett

8

4 Days Ago

Jack Quick

7.9

3 Days Ago

Neil Briscoe

2 Days Ago

Max Davies

2 Days Ago

Marton Pettendy

2 Days Ago