William Stopford

Will 2026 be the year of the people mover in Australia? China seems to think so

13 Hours Ago

Battery manufacturer CATL has announced that it's going to build a $6.8 billion EV battery recycling plant in China.

Contributor

Contributor

China’s Contemporary Amperex Technology Co. Ltd. (CATL), one of the biggest electric vehicle (EV) battery suppliers, is reportedly working on a A$6.8 billion battery recycling facility in the province of Hubei.

Reuters reports the company will use the 32 billion yuan facility to strip out valuable materials, such as cobalt and lithium, from end-of-life EV batteries and re-use them in various types of storage devices.

The battery recycling facility is being created as a joint venture with Hubei Yihua Chemical Industry Co. Ltd.

With EV demand skyrocketing, the supply chain is going to come under increasing strain. Re-using materials as well as mining them should help this while theoretically being better for the environment.

CATL was founded in 2011 as a spin-off of Amperex Technology Ltd. (ATL), which is a previous business founded by the same person, Robin Zeng.

The company specialises in manufacturing batteries for EVs and energy storage systems.

It has numerous manufacturing plants throughout China as well as one plant located in Erfurt, Germany.

It also has four main R&D centres in China and one in Munich, Germany.

According to the company’s 2020 annual report, there were 33,078 employees working for CATL at the time. This is predicted to have grown since then.

CATL produces batteries for a number of well-known automakers including Tesla, Volkswagen Group, BMW, Hyundai, Honda, and Volvo.

Most notably, CATL extended its battery supply deal with Tesla until 2025 according to Reuters in June 2021.

Its lithium iron phosphate batteries are fitted to Model 3 and Model Y vehicles at Tesla’s Shanghai gigafactory.

A portion of the Model 3 examples produced at this facility are manufactured in right-hand drive and exported to Australia.

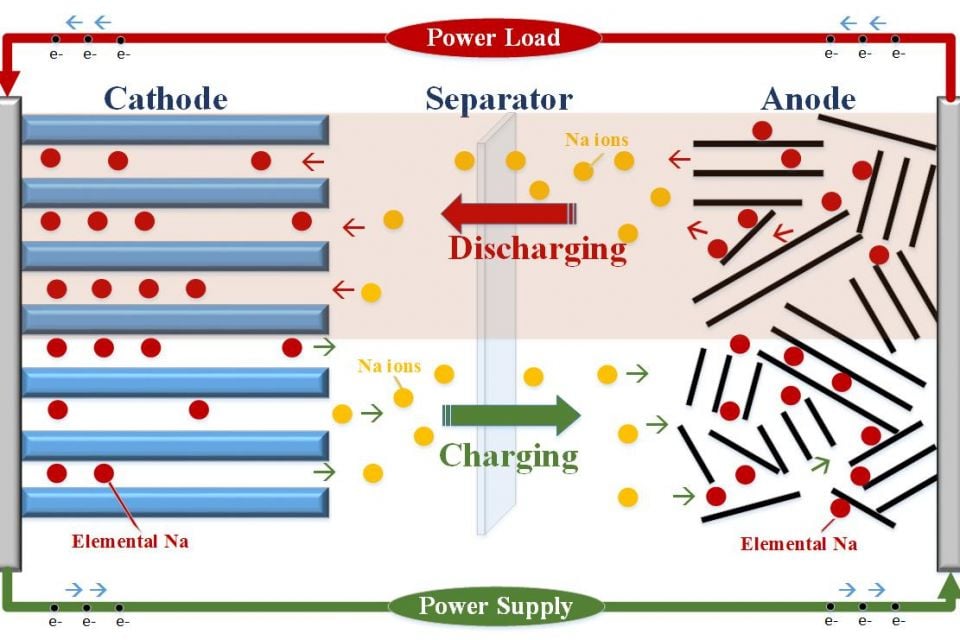

CATL has also been researching the viability of sodium-ion batteries as reported by Reuters.

Working on a hybrid sodium- and lithium-ion battery pack, the company has said the same manufacturing equipment and facilities can be used to produce these batteries.

It has been researching this battery technology for a number of years now and expects production to commence in 2023.

These batteries still contain rare earth minerals such as lithium and cobalt, albeit in smaller amounts.

CATL says that its first-generation sodium-ion batteries will be designed for transport and could eventually replace existing lithium-ion EV batteries.

The Chinese battery giant isn’t alone in developing EV battery recycling centres as Volkswagen Group Components has opened a pilot plant in Salzgitter, Germany.

It’s been able to develop a closed-loop recycling process for recovering raw earth minerals, such as lithium, nickel, manganese and cobalt, from lithium-ion EV batteries.

This pilot EV battery recycling plant has been operational since January 2021 and has been designed to recycle up to 3600 battery systems during the pilot phase according to the company.

MORE: Swedish researchers use salt in new battery chemistry MORE: Volkswagen reveals ‘BattMan’ electric car software

Jack Quick is an automotive journalist based in Melbourne. Jack studied journalism and photography at Deakin University in Burwood, and previously represented the university in dance nationally. In his spare time, he loves to pump Charli XCX and play a bit of Grand Theft Auto. He’s also the proud owner of a blue, manual 2020 Suzuki Jimny.

William Stopford

13 Hours Ago

Max Davies

14 Hours Ago

Derek Fung

15 Hours Ago

Matt Campbell

21 Hours Ago

Ben Zachariah

2 Days Ago

Damion Smy

2 Days Ago