Australian Motor Industries (AMI) was a local company that was instrumental in the setup and expansion of automotive manufacturing in Australia.

Effectively a contract manufacturer, its primary business model revolved around importing complete knock-down kits (CKD) – effectively a collection of unassembled parts – and using them to build a completely operational car.

The company was founded in the latter part of the 1920s and initially called itself ‘Talbot and Standard Motors’, as the original business was to partner with the British Standard Motor Company and build its cars locally.

Australia at the time was well-known for protectionist economic policies, and building cars locally with imported kits was one way to get around heavy import taxes.

The Standard Motor Company acquired Triumph following the end of the second World War, which meant initial models assembled locally by AMI included the Standard Vanguard (a competitor to early Holdens), the Standard Eight, and the Triumph Mayflower.

All were small or medium in size, compact enough to fit on narrow British roads and designed to be affordable to a public that had been battered during the war.

The Standard Eight, produced from 1953, derived its name from its tiny 803cc engine, which produced a grand total of just 19kW and a top speed of only 98km/h.

The 0-80km/h sprint took 26.5 seconds. The car even lacked an external boot release, with the boot only being accessible by folding down the rear seat.

Nevertheless, Talbot and Standard Motors was steadily expanding, and by 1956 employed more than 1600 people at its main assembly plant at Fisherman’s Bend in Victoria.

Soon after, the company moved beyond manufacturing only Standard models, and renamed itself to Australian Motoring Industries (AMI).

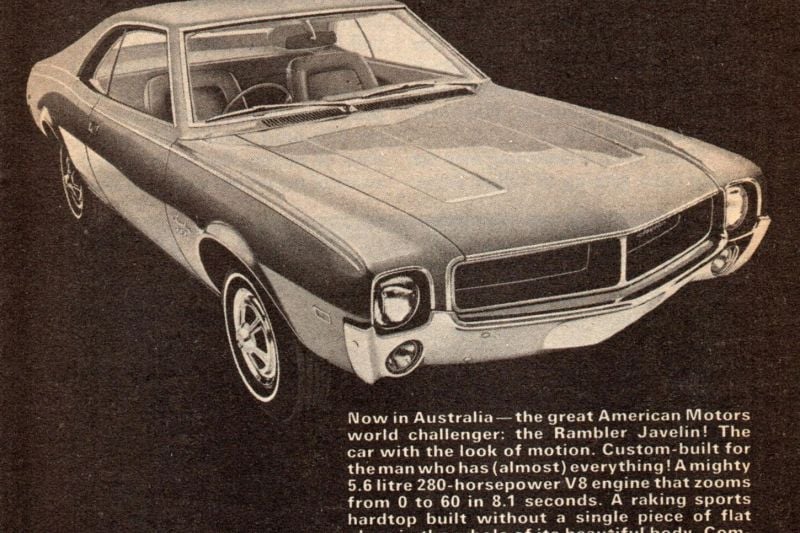

The first non-British cars sold by AMI were models from the now-defunct American Motors Corporation, including the Rambler.

AMI also locally assembled various Mercedes-Benz models, the first being a W180 series Mercedes-Benz 220S. Over time that expanded to also include the 190Db. Although major parts for these cars were imported from Germany they had a sizeable proportion of local content, such as interior trims and upholstery.

Despite the Mercedes-Benz brand name, overall build quality reportedly left much to be desired, with various paint and rustproofing issues making the local models unable to match their imported cousins in this regard.

The Australian economy in the early 1960s underwent substantial changes due to a decision by the Menzies government to end import restrictions. A recession hit as unemployment numbers jumped from 53,000 at the end of 1960 to more than 115,000 by the conclusion of the following year.

Australian businesses suffered, and AMI was no exception. Australian production rights for Mercedes-Benz were pulled, but the company secured the business of then relatively-unknown Toyota to replace it.

With the Tiara in 1963, AMI was the first company to build a Toyota outside Japan. The Tiara was initially sold in Australia for £845, and featured 13 inch wheels with a top speed of around 126km/h. The partnership expanded during the ’60s, with AMI locally producing variants of the Toyota Crown, Corona and Corolla at Fisherman’s Bend.

Toyota production became the main source of revenue for AMI by the end of the 1960s.

Cars originally sourced from the USA also remained a niche market – and AMI was the only source for ‘US Origin’ vehicles during the 1960s and ’70s. In many cases, these vehicles came with a higher level of standard specification than their counterparts sold in the USA.

The post-war Japanese economy grew rapidly, and Toyota recognised the success of models made in Australia by AMI.

Toyota in Japan began a gradual process to buy AMI entirely. This commenced with an initial 10 per cent shareholding, which was then gradually increased to 50 per cent by the 1970s.

A public company, AMI delisted itself from the ASX in 1987 following the complete buyout by Toyota.

Perhaps the spiritual end for the company occurred in 1994, when Toyota shifted production from the former AMI plant in Fisherman’s Bend to an all-new facility in Altona.