William Stopford

Will 2026 be the year of the people mover in Australia? China seems to think so

18 Hours Ago

Another part of the Toyota empire, Aisin has produced everything from aircraft engines to mattresses and automatic transmissions

Contributor

Contributor

With Toyota being the largest player in the Japanese automotive industry, it is not uncommon to see cities or regions of the country that have their economy dominated by the Toyota keiretsu.

The city of Kariya in Aichi Prefecture, Japan, is one of these places. A 20km hop from Toyota’s headquarters (in Toyota city, no less), Kariya is home not just to Denso, but also Aisin, another member of the Toyota group of companies.

Today, Aisin excels primarily as a maker of transmissions. That marriage between Toyota and BMW that produced the Supra and Z4? In a sense, it goes deeper.

The development of BMW vehicles on its new FAAR platform, such as the new 1 Series and 2 Series Gran Coupe, has resulted in a switch from RWD to FWD and a change in transmission supplier, with Aisin rather than ZF producing the automatic transmission.

Through subsidiary companies, Aisin also produces other components such as the satellite navigation system integrated within Audi’s Virtual Cockpit, for Audis sold specifically in Asian markets including Japan, China, and Korea.

Aisin’s expertise in transmissions and other automotive components has enabled it to become the sixth-largest supplier based on sales revenue to automotive OEMs (2018 numbers), just behind competitor ZF and ahead of Hyundai Mobis.

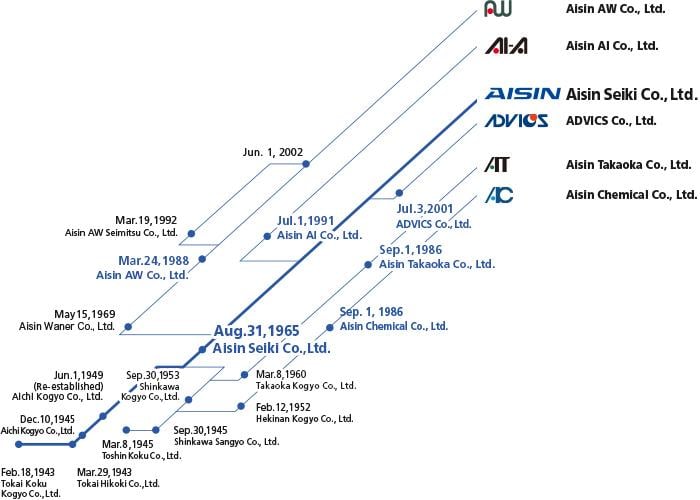

The wider Toyota firm was already an established enterprise by the onset of WWII. With Japan in a total war situation during much of this time, Aisin was established by Kiichiro Toyoda (the founder of Toyota Motor Corporation) in 1943 to supply parts for aircraft engines.

Originally named Tokai Aircraft Company, the firm transitioned to the manufacture of more mundane products such as sewing machines, and gradually automotive parts, after the war.

The automotive business became the company’s new focus, and it was able to readily find business as a feeder firm for parent Toyota.

Named Aisin Seiki Co. Ltd after a merger with Shinkawa Kogyo Co. Ltd in 1965, the firm followed in cousin company Denso’s footsteps by pursuing partnerships with international companies to increase the depth and breadth of its technical expertise.

To this extent, the company entered into a collaboration with ZF to produce gears for power steering systems in 1969, and established a joint venture with American supplier BorgWarner to build automatic transmissions in the same year.

Much like other Japanese companies at the time, Aisin’s business expanded in line with the rapidly growing Japanese economy during the 1970s and ’80s. Hand-in-hand with this came a rigorous focus on quality, with the firm winning the famed Deming prize for total quality management in 1972.

The company grew more ambitious during this period, and moved beyond transmissions and other gear-based components to build other parts for vehicles including sunroofs and seat parts.

Production also expanded beyond Japan to the USA, with the product range including sunroofs and heat humps for automotive air-conditioning systems.

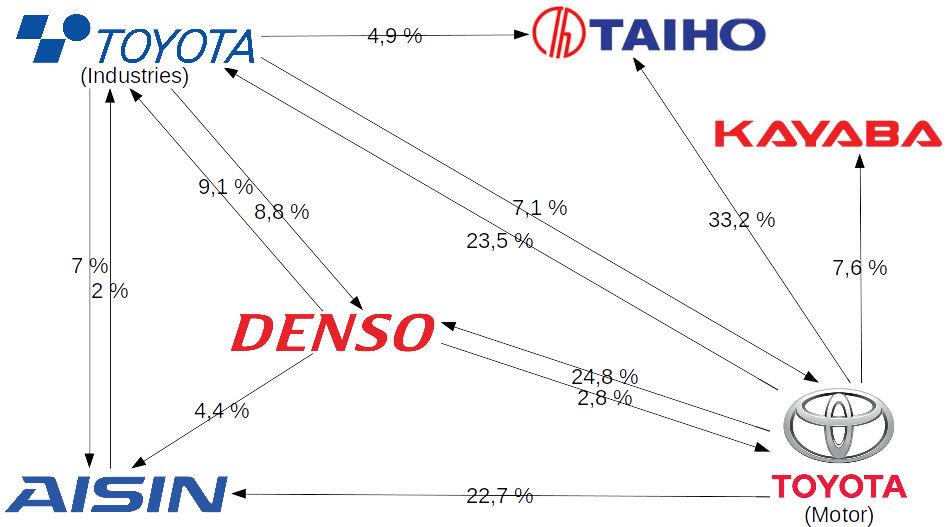

As alluded to earlier, Aisin is part of the Toyota group of companies. Through cross-shareholdings from Toyota Motor Corporation and other keiretsu firms, the rest of the Toyota group owns a substantial amount of the shares in Aisin.

Additionally, Toyota Motor Corporation (alongside other Toyota group companies) remain the company’s largest customers.

Despite its size, Aisin and the wider Toyota group is a family business of sorts for the founding Toyoda family.

Aisin’s current chairman, Kanshiro Toyoda, is an extended relative of Akio Toyoda (Toyota Motor Corporation’s current president), and Toyoda family members also hold board or chairman roles at companies that are part of the Toyota keiretsu, including cousin and fellow supplier Denso.

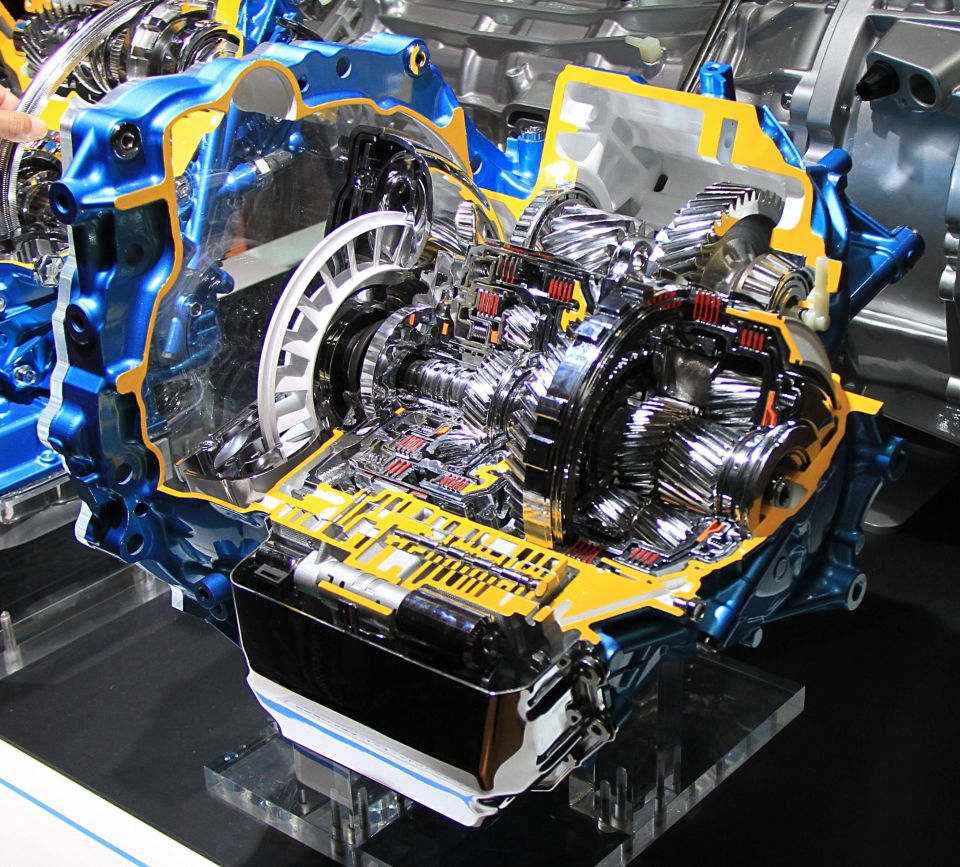

In the automotive space, one of Aisin’s most significant modern innovations has been the development of the world’s first eight-speed torque converter automatic transmission for transverse engines – where the engine is parallel with the front axle, typically used in front-wheel drive applications.

This transmission has seen usage in a variety of applications from car manufacturers around the world, through models ranging from the Lexus RX and BMW X1, to the Peugeot 308, Volvo XC40 and XC60, as well as variants of the Toyota RAV4.

As a company specialising in the manufacture of transmissions, Aisin has also undertaken research in the field of quantum computing for automotive applications, in partnership with Silicon Valley company QC Ware.

Aisin believes quantum computing can have a multitude of applications within the automotive space, including resolving various logistical challenges and improving quality assurance for automatic transmission software.

In recent times, the company’s R&D activities have extended beyond the automotive space as part of the culture of monozukuri, which can perhaps be broadly defined as taking pride in craftsmanship and being a maker of things.

One of these is the Aisin Super Flex Fit Mattress. The company sought to develop a mattress that would support the body during rollover and turning movements (e.g. from side sleeping to back sleeping) during sleep.

The company’s research indicated two types of rollovers occurred whilst sleeping – necessary and unforced rollovers.

Necessary rollovers helped maintain a regular, 90-minute cycle of deep and light sleep.

Meanwhile, unforced rollovers maintained blood circulation by dispersing pressure being exerted on parts of the body that were in contact with the sleeping surface, such as the buttocks (which was typically more of an issue with firm mattresses).

The company’s research was able to successfully produce a mattress with a ‘staggered arrangement’ structure, that was comfortable enough to disperse body pressure and minimise forced rollovers but supportive enough to assist with necessary rollovers.

The Aisin Super Flex Fit Mattress is now available for sale in Japan.

William Stopford

18 Hours Ago

Max Davies

18 Hours Ago

Derek Fung

19 Hours Ago

Matt Campbell

1 Day Ago

Ben Zachariah

2 Days Ago

Damion Smy

2 Days Ago