A spoonful of sugar helps the electric car go far.

Researchers at Monash University have developed an alternative to traditional lithium-ion batteries that uses sweet, sweet sugar instead of cobalt and rare earth minerals.

Assisted by CSIRO, the team found a glucose-based additive could stabilise lithium-sulfur batteries, which are said to store two to five times more energy than the lithium-ion batteries commonly found in today’s electric vehicles.

The team says this could lead to vehicles like electric buses and trucks travelling from Melbourne to Sydney – over 870km – without recharging.

Prototypes made by the team have been found to have a charge-discharge life of at least 1000 cycles – comparable to an equivalent lithium-ion battery, while holding more capacity.

“So each charge lasts longer, extending the battery’s life,” says first author and PhD student Yingyi Huang.

“And manufacturing the batteries doesn’t require exotic, toxic, and expensive materials.”

The team’s research was published this month in the journal Nature Communications.

The hurdle with lithium-sulfur batteries is their electrodes can deteriorate rapidly, with the positive sulfur electrode expanding and contracting and making it inaccessible to lithium, while sulfur compounds contaminate the negative lithium electrode.

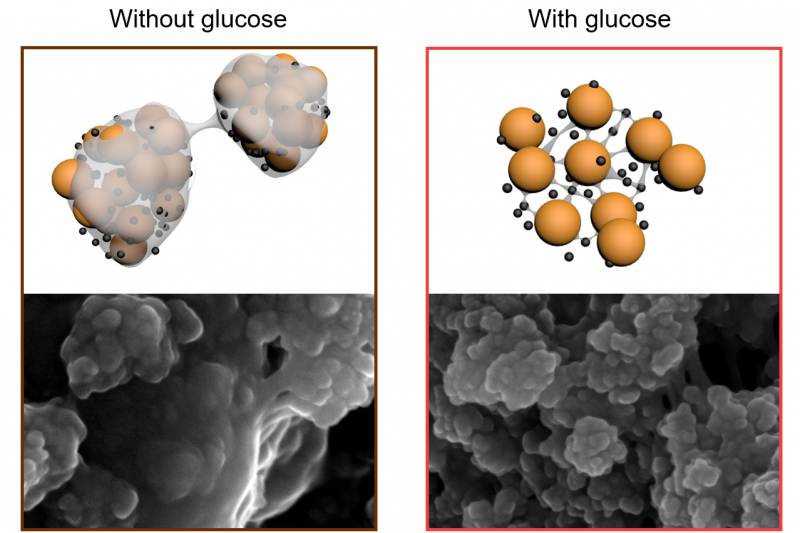

The team had demonstrated last year it could open up the structure of the sulfur electrode and make it more accessible to lithium, and now it says by introducing sugar into the electrode it can stop the sulfur from moving.

The researchers say they’ve solved many of the challenges on the cathode side of the battery but there’s still work to be done on the protection of the lithium metal anode, though they say such innovations “may be right around the corner”.

That likely means a commercially-viable product won’t be around for some time yet.

The Australian Government has supported the battery research program via CSIRO, the Australian Research Council, and the Department of Industry, Innovation and Science, while the Australian subsidiary of the Enserv Group of Thailand has also supported this research.

The latter is looking to develop and manufacture batteries in Australia, currently the world’s largest producer of lithium.

“We would be looking to use the technology to enter the growing market for electric vehicles and electronic devices,” says Enserv Australia managing director Mark Gustowski.

“We plan to make the first lithium-sulfur batteries in Australia using Australian lithium within about five years.”

Lithium-ion batteries use materials like cobalt, nickel and manganese, which are in increasingly short supply.

There are also ethical concerns regarding the sourcing of cobalt. Not only is it difficult to mine, it’s often sourced from countries with questionable labour practices.

The Democratic Republic of Congo is rich in cobalt, for example, but reports of child labour and dangerous working conditions are rife.

The precious metal is also heavy and expensive, but it’s commonly used in battery cathodes because it’s stable and allows cells to be more energy dense.

Lithium-sulfur batteries, in contrast, don’t use these rare earth minerals and are therefore cheaper to produce.