Josh Nevett

2025 Bentley Bentayga review

5 Days Ago

Contributor

Porsche has officially opened the Chilean production plant for its synthetic eFuel, marking the occasion by filling up a 911.

Working in partnership with Highly Innovative Fuels (HIF), in which it bought a 12.5 per cent stake this year, Porsche has been developing a synthetic fuel option for combustion engines in parallel with its rollout of electric vehicles.

The Haru Oni pilot plant in Punta Arenas, Chile is powered by wind energy, and will eventually be supported by plants in the US and Australia.

The Australian plant will be located south of Burnie, Tasmania and construction is scheduled to begin in 2024, with an aim to produce 100 million litres of eFuel a year starting in mid-2026.

In this initial pilot phase at the Chilean plant, Porsche has set an annual production target of 130,000 litres.

The first litres were used in a ceremonial fuelling of a Porsche 911 by Porsche Executive Board members Barbara Frenkel and Michael Steiner.

Porsche has projected that output will increase to 55 million litres per year by the middle of the decade and around 550 million litres just two years after that.

For reference, the Australian Department of Climate Change, Energy, the Environment and Water, says Australia used 15,500 million litres of automotive fuel in 2021.

Synthetic fuel production will have to significantly rise before it can become a wide-scale solution, with Porsche saying that the initial units of eFuel will mostly be used for ‘promotional purposes’ until production ramps up.

The Porsche eFuel will initially be used in ‘lighthouse projects’ where the brand can showcase the fuel’s performance, such as the Porsche Mobil 1 Supercup.

The south of Chile, where the plant is located, has around 270 windy days a year, making it an ideal location for wind turbines operating at full capacity. The plant is located close to the Strait of Magellan.

The fuel can also be transported using existing infrastructure, further mitigating any environmental damage.

The production of eFuel is just one aspect of Porsche’s plan to be entirely CO2-neutral by 2030, and the company says it has already invested over $US100 million ($A150 million) into the mission.

“The potential of eFuels is huge. There are currently more than 1.3 billion vehicles with combustion engines worldwide. Many of these will be on the roads for decades to come, and eFuels offer the owners of existing cars a nearly carbon-neutral alternative,” said Mr Steiner, member of the executive board for development and research

Ms Frenkel, member of the executive board for procurement, said that this eFuel endeavour will work as part of a two-pronged approach to sustainability, in conjunction with the company’s push towards EVs.

“Porsche is committed to a double-e path: e-mobility and eFuels as a complementary technology. Using eFuels reduces CO2 emissions,” said Ms Frenkel.

“Looking at the entire traffic sector, the industrial production of synthetic fuels should keep being pushed forward worldwide.

“With the eFuels pilot plant, Porsche is playing a leading role in this development.”

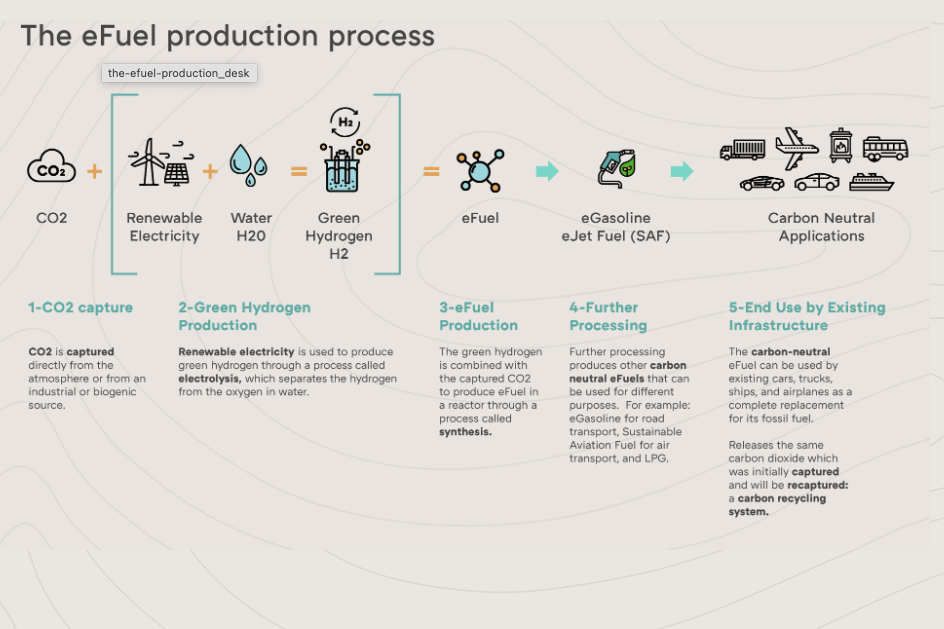

The company says the process of producing eFuels involves capturing CO2 from the atmosphere or from a biogenic source. Green hydrogen is then produced using electrolysis, and this is then combined with the CO2 in a reactor to create the fuel using synthesis.

Compared to conventional fossil fuels, which have between 30 and 40 components, synthetic fuels have as few as eight.

There are fewer nasties hiding in eFuel, so it’s better for engines and the environment. Porsche says it reduces emissions by around 85 per cent compared to today’s unleaded.

Along with sports cars like the 911, where noise and emotion are central to the experience, Porsche says eFuels can be used to help cut carbon in remote areas or less developed markets, where the transition to electric power will be slower compared to the world’s big cities.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Josh Nevett

5 Days Ago

Andrew Maclean

4 Days Ago

Shane O'Donoghue

4 Days Ago

Anthony Crawford

3 Days Ago

Matt Campbell

2 Days Ago

James Wong

18 Hours Ago

Suggested Comparisons