James Wong

4 Days Ago

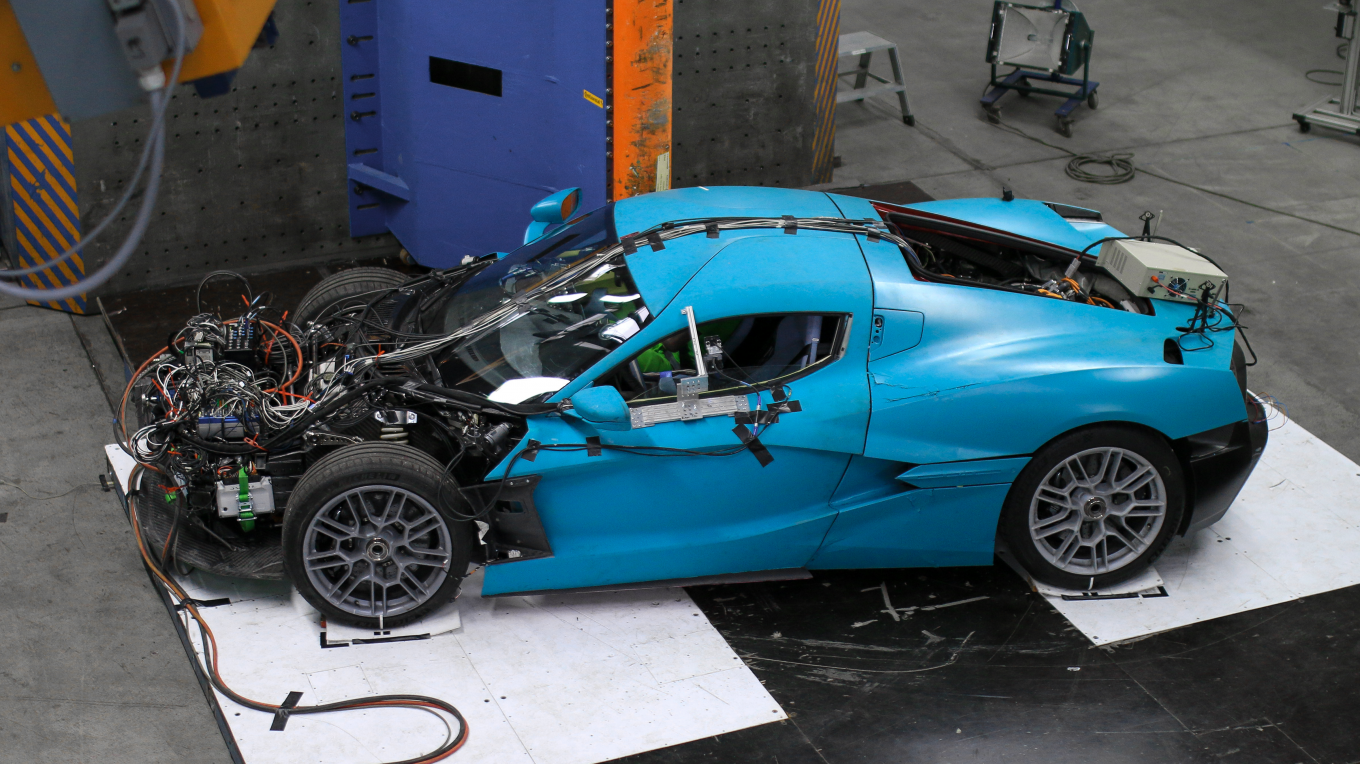

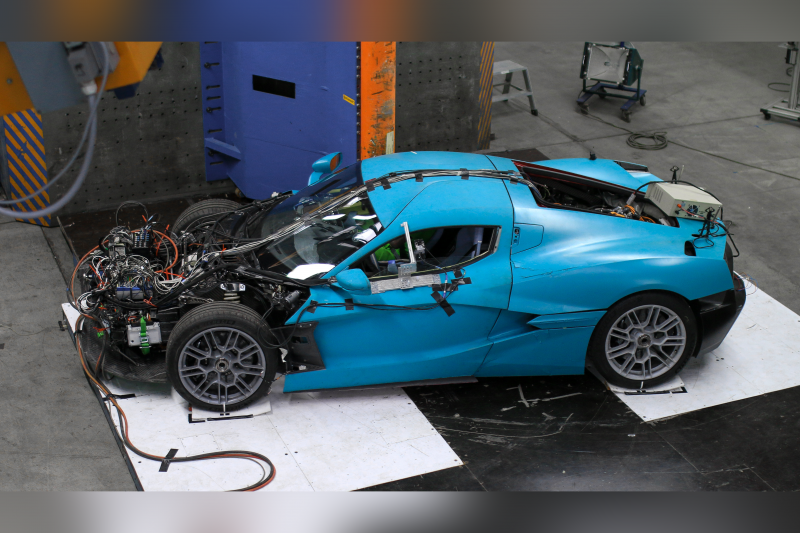

This global homologation program began four years ago, with thousands of digital simulations completed and nine complete vehicles destroyed.

The Rimac Nevera all-electric hypercar has now completed its rigorous crash test program required for global homologation.

Just like regular cars, hypercars like the Nevera are required to pass certain safety tests so it can be legally sold through the official channels around the world.

This is even more important when you take the Nevera’s insane 1.85 second 0-100km/h sprint time and its 412km/h top speed into account.

Powered by a quad-electric motor setup, the Nevera produces an other-worldly 1427kW of power and 2360Nm of torque. This is mated to a 120kWh lithium-manganese-nickel battery that’s located primarily along the car’s centre tunnel and designed in-house by Rimac.

The Croatian hypercar manufacturer claims the Nevera has a range of 547km according to WLTP tests.

With prices starting from €2 million ($3.16 million) in Europe, there’ll only be 150 Neveras made with each example will be tested and signed off by company founder Mate Rimac before final delivery.

This global homologation program began four years ago, with thousands of digital simulations completed and nine complete vehicles destroyed.

In total, Rimac Nevera prototypes were subjected to a total of 45 different physical crash tests, and “many more” static passive safety tests.

The final one, which took place at the end of January, was the 32km/h side pole test that simulates a side impact with a lamp post. It was required for the US homologation specifically.

Rimac says that all the Europe homologation tests for the Nevera were completed in 2021.

Despite a physical crash test impact taking 80 milliseconds, it takes the computers 20 hours to process what happened.

The test dummy occupant experienced up to 25G of lateral acceleration during the side pole test, but experienced up to 41G during the frontal wall crash test at 56km/h.

The highest impact speed a Nevera prototype experienced during the crash test program was the US-market rear crash test, which was completed at 80km/h.

Rimac says the Nevera was designed to be “extremely safe” from the start and is built around a carbon fibre monocoque that extends between the front and rear suspension attachments.

Claimed to be the “stiffest production car ever created”, Rimac says the Nevera has a torsional rigidity of 70,000Nm per degree and the roof can resist more than three times the weight of the car.

With all of the formal homologation crash tests now complete, we now just have to wait until Rimac manufactures a production-ready Nevera.

Rimac Group, which encompasses the Bugatti Rimac joint venture and the Rimac Technology electric vehicle (EV) component company, is currently in the process of constructing its new €200 million ($316 million) headquarters in Zagreb, Croatia.

Titled as the ‘Rimac Campus‘, it’ll serve as the company’s international research and development (R&D) and production base for all future Rimac products, including the Nevera, and their key components.

Ground has already been broken at the construction site and the headquarters is expected to be completed in 2023.

This campus will also become the home of R&D for future Bugatti models, but the French hypercar manufacturer will continue to produce its cars at its own production facilities.

Across a 112,980 square metre gross floor area and 197,575 square-metre site area, this complex will feature an on-site test track, museum, design, engineering, production and testing facilities, as well as “high-end customisation” showroom, bar, restaurant and retail spaces.

Rimac also touts there’ll be a gym and training centre, kindergarten, auditorium, conference hall, education rooms, rooftop garden, command centre, VR-rooms and several top-secret project rooms.

MORE: Rimac Nevera unveiled

Jack Quick is an automotive journalist based in Melbourne. Jack studied journalism and photography at Deakin University in Burwood, and previously represented the university in dance nationally. In his spare time, he loves to pump Charli XCX and play a bit of Grand Theft Auto. He’s also the proud owner of a blue, manual 2020 Suzuki Jimny.

James Wong

4 Days Ago

Andrew Maclean

4 Days Ago

Josh Nevett

8

3 Days Ago

Jack Quick

7.9

2 Days Ago

William Stopford

2 Days Ago

William Stopford

2 Days Ago