CarExpert.com.au

The CarExpert team's favourite cars of 2025

4 Hours Ago

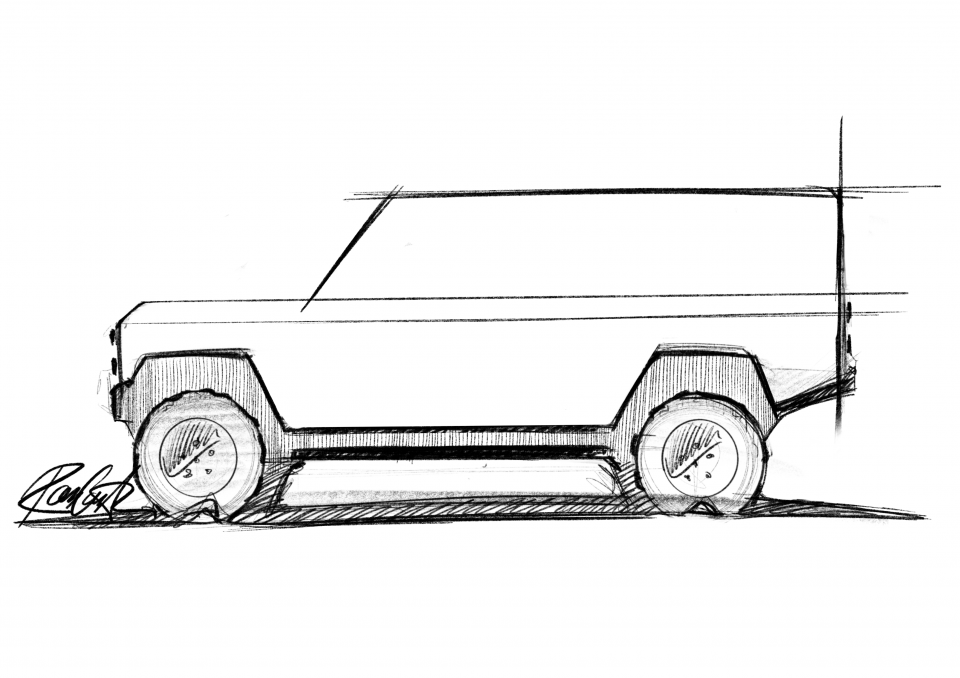

A boutique Scottish company is making off-road EVs designed to last for decades. It's called the Munro Mk_1.

Senior Contributor

Senior Contributor

Scottish startup Munro Vehicles has unveiled its first model, the MK_1, which it calls “the world’s most capable all-electric 4×4”.

The off-road EV, set to enter small-scale production from 2023, is said to offer a 1000kg payload, 3500kg towing capacity, and a 16-hour off-road duty cycle on a single battery charge.

It’s thereby designed as a zero-emissions option for users involved in construction, agriculture, mining, environmental, emergency rescue, remote infrastructure maintenance, and recreation “without compromising on performance or capability”, according to its maker.

“Intensely focused on off-highway performance, reliability, ease-of-repair and longevity, the Munro is engineered to provide owners and operators with decades of service,” it added.

The MK_1 will be priced in Britain from £49,995 ($A90,000) in five-door, five-seat, 130-inch wheelbase ‘Utility’ guise, with Munro claiming to hold a few deposits already, as well as orders from the UK, Switzerland, St Lucia, and Dubai.

While the first batch will be hand-made next year, in 2024, Munro will move to a new purpose-built factory in central Scotland, where production is intended to scale to more than 250 units per year initially, and ramp to 2500 per annum by 2027.

Munro claims it will be the first automotive manufacturer to build cars at scale in Scotland since Peugeot-Talbot closed its Linwood plant in 1981.

The specs

Munro selected an axial flux electric motor, which is said to weigh half as much as a more common radial flux unit due to higher power density. It’s located between the two front-seat occupants in front of the vehicle’s bulkhead.

The Munro’s axial motor spins between 5000 and 8000rpm, much slower revolutions than is common. This negates the need for a reduction drive, enabling drive to be taken directly to the transmission transfer case from the motor. By combining with a two-speed transmission, the motor can work at low speeds with greater efficiency, Munro claims.

When the Munro is in high-gear Drive mode, lifting off the accelerator provides a degree of regenerative braking. But in low-gear ‘Off-Road’ mode the regenerative braking is much more pronounced, enabling one-pedal driving.

The Munro features a heavy-duty mechanical braking system using non-vented as opposed to vented discs which can become clogged in terrain.

The Munro is offered with a choice of two electric motors, making 220kW and 280kW, and two battery packs with energy capacities of 61kWh or 82kWh – the latter offering more than 300km of claimed driving range.

While the 280kW version sprints to 100km/h in a claimed 4.9 seconds, it’s not really a vehicle that prioritises straight-line punch. Peak torque of 700Nm is only available up to 50mph (80km/h), which enhances low-speed crawling and towing capacity.

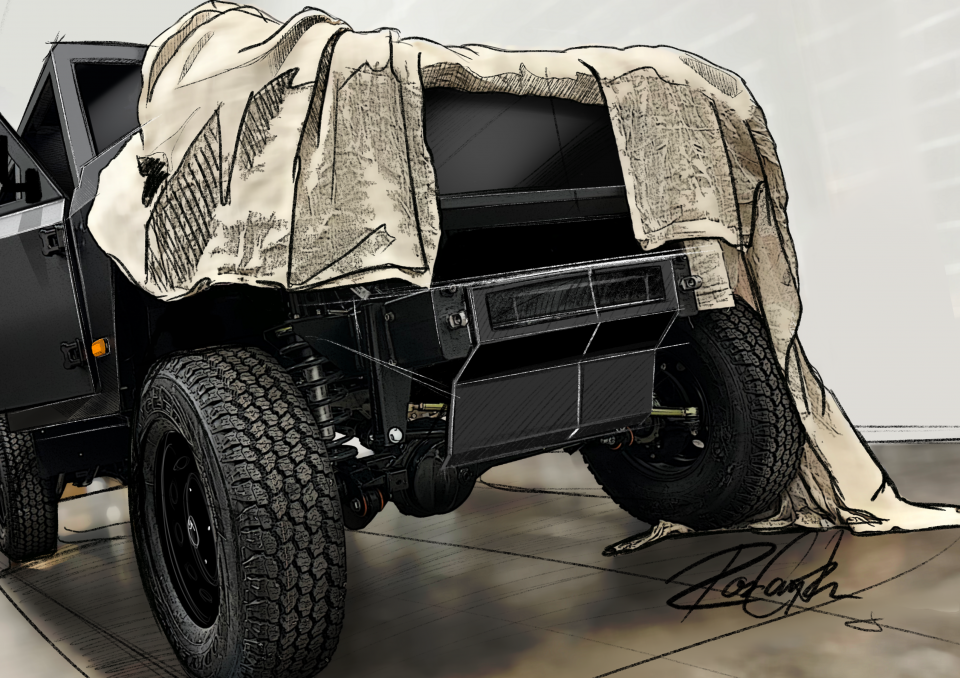

The battery pack comprises 35 lithium NMC modules mounted in three heavy-duty aluminium boxes underneath the vehicle. This arrangement “ensures it is quick, convenient, and inexpensive to replace individual battery modules if required”, Munro added.

“With your average electric vehicle, the battery is designed to last the life of the car, so in most cases, customers will never have to worry about replacing it. But because the Munro is engineered to last several decades, we will either recondition or replace the battery pack for customers when the time comes,” said head of powertrain Ross Anderson.

The Munro is offered with either 7kW or 22kW AC charging, as well as CCS-type DC charging.

Munro claims at no point did it consider using a ‘skateboard’ chassis with two electric motors. Instead, the priority was to equip the Munro with a single, central-mounted electric motor providing power to a mechanical four-wheel-drive system.

“The best way to drive off-road is to ensure that the same amount of torque is delivered to each wheel and that all the wheels spin at the same speed. And no matter how clever your computer is, you’re still going to have problems if you’ve got a split driveline in the vehicle,” the company contends.

It sits on a galvanised steel ladder chassis constructed with 5mm thick steel. Munro builds its own axles and uses a combination of aftermarket and “motorsport-derived components” for the rest of the mechanical driveline – by motorsport we mean off-road racing.

Off-road prowess is enhanced by a massive 480mm ground clearance, and the claimed ability to wade through water up to a depth of 800mm. The radical design allows 84- and 51-degree approach and departure angles, plus a 148-degree break over angle.

Before its global unveil, the MK_1 was subjected to an intensive two-year test programme, tackling some of Scotland’s most demanding conditions in all weather (let’s be honest here, it was almost certainly mostly mud and rain!).

The body is mounted to the chassis at eight points. The company says while it initially outsourced production of the body, the aluminium panels are now laser-cut, formed, and folded on-site before being moved a few metres to the company’s paint shop.

The MK_1 is designed to handle a 1000kg payload and a standard Euro pallet in the load bay. There are also two front-side lockers designed to carry charging cables, larger tools, or wet weather gear.

The interior uses lots of industrial switchgear, says Munro CEO Russell Peterson.

“The switches will be familiar to anyone using farming equipment… they can be operated with gloves on, they’re fully waterproof, so with the hardwearing floor and door surfaces, the whole vehicle can be power washed from waist height down,” Mr Peterson added.

“The switches are almost impossible to break, but if they get damaged, they are quick, easy, and inexpensive to replace.”

The Munro is offered with a choice of low- and high-power DC converters for running ancillaries such as winches and light bars. In addition to two USB C sockets and two wireless charging pads, the MK_1 is equipped with two three-pin household sockets.

The dashboard features a deletable double DIN screen, compatible with Android Auto and Apple CarPlay. It can also be upgraded with a superior unit or replaced with a UHF two-way radio.

In terms of sales, Munro says it will select a series of agents to market the MK_1 but will not establish a traditional dealer network. Each vehicle will come with a five-year/160,000km warranty.

“We recognise and respect our customers’ right to repair and maintain their vehicle, and their doing so will not invalidate the warranty,” the company added.

Background

Munro launched in 2019 with private funding provided by Mr Anderson and Mr Peterson, and a further injection of capital was raised in late 2021.

“We had already taken measures to reduce our own environmental footprints and had a lot of experience driving our own EV, and got quite used to the instant torque delivery,” recalls CEO Peterson.

“But the off-roader we were driving through the Highlands was combustion-engined, and it was really struggling on the steep climbs. So, we were musing how much better it would be with an electric motor.

“On the return journey, we stopped at a café in Braemar, where a bank of 50kW rapid chargers were sitting empty and unused. Parked up nearby was a large group of combustion-engined safari adventure 4x4s of a type that are no longer manufactured and will have to be replaced eventually.

“It dawned on us that there was a gap in the market for an electric-powered, four-wheel-drive, utilitarian workhorse. We envisioned a vehicle with ultimate, go-anywhere, off-road ability, unrestricted by road-derived underpinnings that limit the all-terrain ability of vehicles such as the 4×4 pick-up trucks that have come to dominate the market.”

On a side note, we reckon this thing might have legs here in Australia, particularly the mining sector where low mileage and poor ventilation are common factors…

CarExpert.com.au

4 Hours Ago

Damion Smy

18 Hours Ago

Damion Smy

21 Hours Ago

Damion Smy

1 Day Ago

Damion Smy

1 Day Ago

Damion Smy

1 Day Ago