Jack Quick

8.4

6 Days Ago

Ever wondered why there are so many different types of 'automatic' transmission out there? Here's a rundown on the different types.

Journalist

Journalist

The basic layout of a car has an engine or electric motor driving the wheels through a transmission. You put your foot on the accelerator, the engine spins faster, and the car speeds up.

Most mainstream petrol engines spin between 800 and 6000 times every minute (hence rpm), but between 60km/h and 110km/h the average wheel will turn between 700 and 1250 times per minute.

If the wheels were directly connected to the engine, most of its usable rev range, not to mention most of its power and torque, would go unused.

To fix that we could use a reduction gear, or a single-speed transmission, to match the two spinning rates and free up more of the engine’s operating range.

With such a setup, though, the engine would drone at around 5000rpm on the freeway, which would be hard on your ears, the environment, and your wallet, not to mention the poor car itself.

Additionally, at lower speeds the engine would be slugging along at infeasibly low revs, and getting up to cruising pace would require the patience of a monk.

The simplest, lightest way to have a bunch of gear ratios is to let the driver handle the shifting themselves.

A clutch is used to connect or disconnect the engine from the transmission and wheels.

When the driver wants to change gears, they depress the clutch pedal in the cabin, and the clutch decouples the transmission from the engine.

With the engine and wheels free to spin at their own speeds, the driver can change gears. To reconnect the engine to the wheels, the driver releases the clutch pedal and the two reengage.

In practice, driving smoothly requires finessing the clutch and accelerator.

Drivers also need to manually (heh) cut the connection between the wheels and engine at standstill by disengaging the clutch, as internal-combustion engines can’t idle at zero revs.

For much of the history of the car, a manual was the fastest, most efficient option.

Now, automated transmissions are not only more convenient but – thanks to modern electronics – faster and more fuel efficient.

In Australia and the USA, manual transmission are now primarily found on entry-level models and select sports cars.

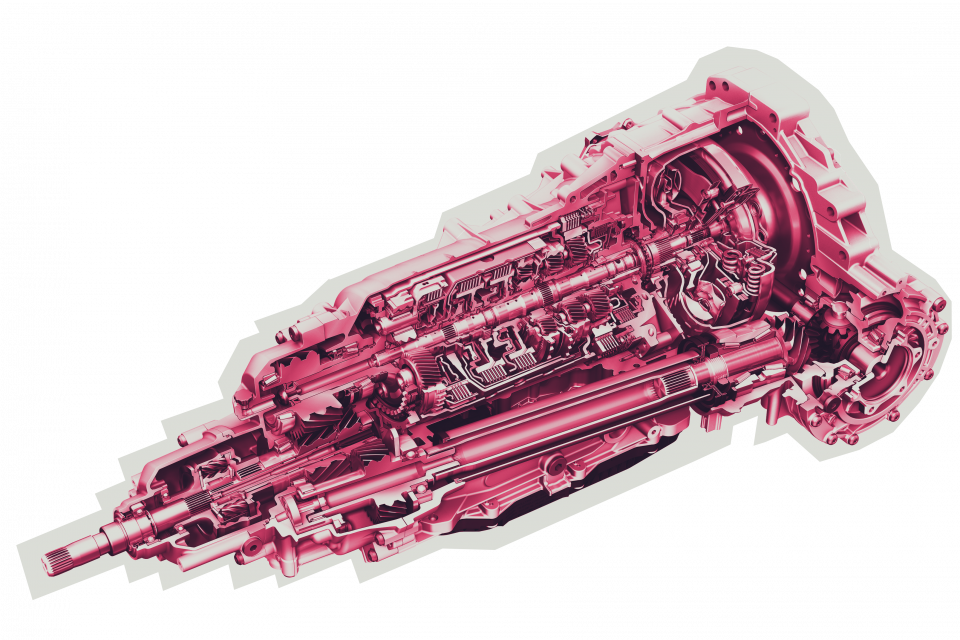

In theory the easiest way to come up with an automatic transmission is just to automate the clutch with hydraulics.

Many automakers have tried their hand at perfecting an automated transmission (AMT), but by and large the results have been ranged from barely acceptable to pretty darn awful.

These transmissions usually feature at least two modes: fully automatic, or manual, where the driver chooses the gears using an up/down shifter or paddles.

Operating fully automatically, many transmissions make changes that are either jerky or overly slurred. Lifting off the accelerator helps to smooth things out in manual mode, but this rarely matches a moderately well-driven manual manual.

Because an AMT is, basically, a manual transmission with some extra hydraulics and electronics to control the clutch, they are cheaper, lighter, and simpler than a traditional automatic.

It’s for these reasons — as well as the usual European preference for manuals — some budget-friendly European cars have been offered with an automated manual transmission instead of a traditional torque converter.

At the higher end of the price and performance spectrum, some luxury sports cars have been sold with AMTs primarily because of their faster shift times.

Also known as: semi-automatic transmission, Servotronic (Citroen), Selespeed (Alfa Romeo), R-Tronic (Audi), and Sequential Manual Gearbox (BMW).

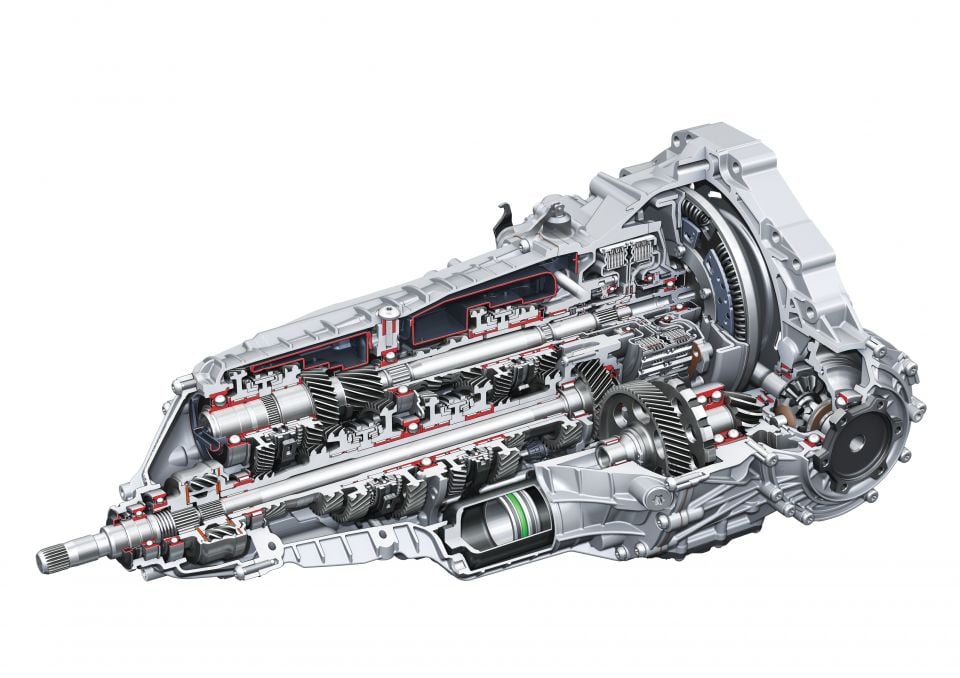

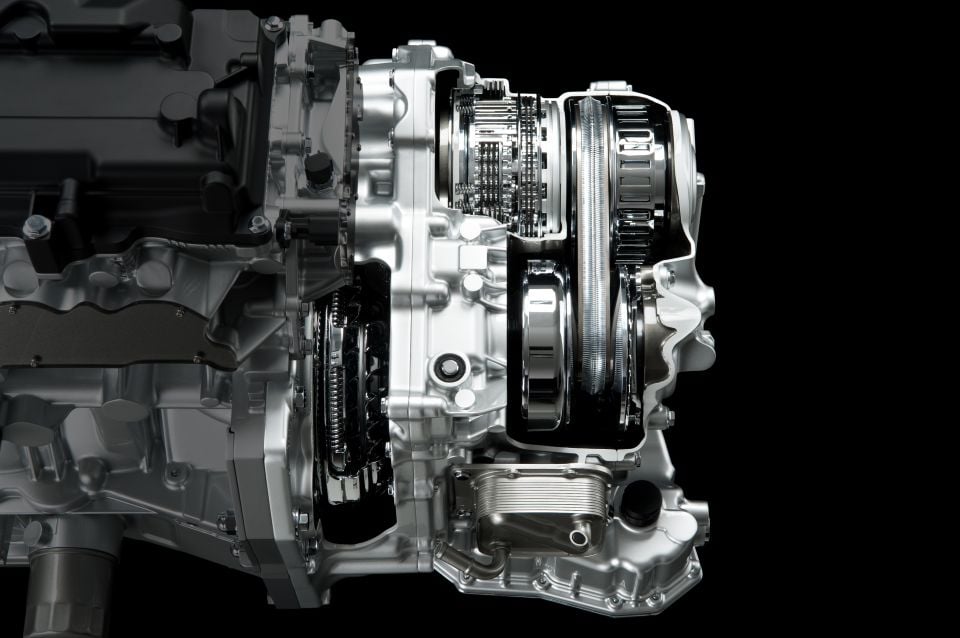

Regular automatic transmissions use a torque converter instead of a clutch as an intermediary between it and the engine.

One end of the torque converter spins at the same speed as the engine, churning the viscous fluid inside and spinning the other end of the device, which is connected to the transmission and, by extension, the wheels.

When the car is stopped with brakes on, the engine idles and spins the fluid inside the converter harmlessly.

Release the brakes, and the spinning fluid will begin to turn the cogs in the transmission, which in turn rotates the wheels, allowing the car to creep forward.

Because the fluid acts as a loose coupling between the engine and the transmission, gears can be changed without needing to finesse a clutch or precisely match engine and wheel speeds.

While a manual gearbox is a collection of gears with different ratios, an automatic has a different design.

Inside are a number of planetary gear sets, each consisting of a sun, planet, and ring gear. Each one of these units can be held in place, left to freely rotate, or be spun by the engine.

By changing the function of each element, the transmission can achieve different gear ratios.

As the wheels are driven indirectly via the churning fluid in the torque converter, some energy is lost. This, along with the added weight and fewer gears, has historically been why automatic transmissions were less fuel efficient than their manual counterparts.

To help overcome this, modern automatics feature a lockup mechanism, which is basically a clutch within the converter that engages at a set speed.

Recent internal design and technology advances have improved automatic shift times. Combined with the proliferation of gears, some automatic drivetrain combinations are more fuel efficient than their manual equivalents.

Also known as: Tiptronic (Porsche), G-Tronic (Mercedes-Benz).

As we’ve discussed earlier, it’s not practical for internal-combustion engines to have a single gear as typical engines are redlined between 4000rpm (diesel) and 6500rpm (petrol).

Electric motors, though, can spin up to 20,000rpm. They also have a broad power band, and maximum torque available instantaneously.

Additionally, while internal combustion engines keep on spinning at idle, an electric motor can come to complete stop. This means most electric vehicles only need a single-speed transmission.

That said, early versions of the Tesla Roadster had a two-speed setup, while the Porsche Taycan comes with a two-speed transmission for the rear motor to improve off-the-line acceleration and high-speed efficiency.

These multi-speed transmissions permit the use of smaller and more efficient motors, but add complexity to the drivetrain.

For much of the history of the mass-produced car, transmission options were pretty binary: manual or automatic.

As fuel economy and emissions rules have tightened and carmakers have sought new ways to make their vehicles faster to an arbitrary speed, different forms of automated transmissions have hit the market.

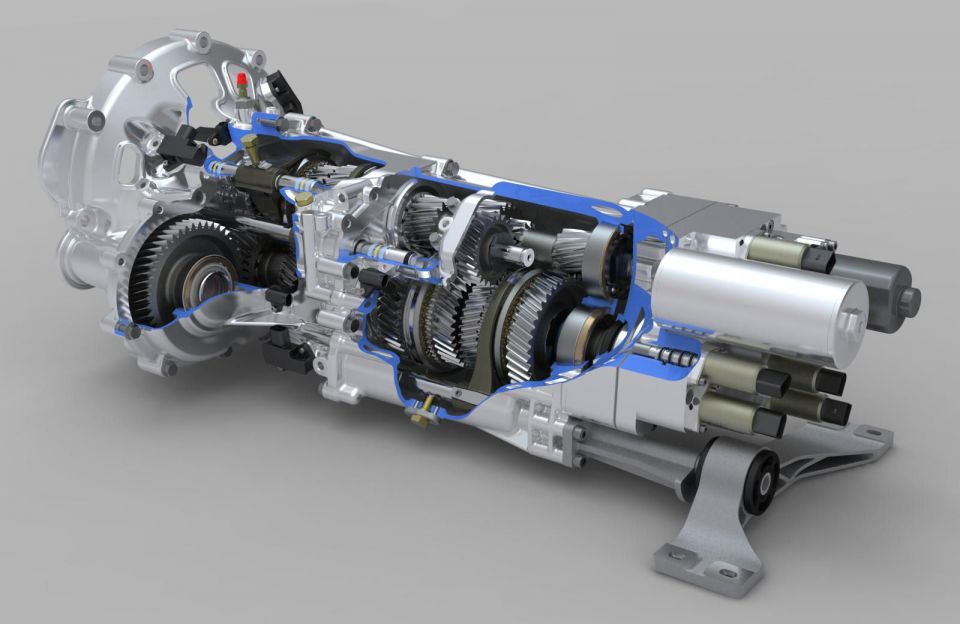

The dual-clutch transmission (DCT) has been pushed aggressively by the Volkswagen Group as a replacement for the traditional automatic.

In a dual-clutch transmission there are two driveshafts, one for even-numbered gears and one for odd-numbered ones – and each shaft has its own clutch.

If you’re accelerating from a stop sign in first gear, the transmission will have second gear preselected. When the car is ready to change gears, the clutch for the odd gears is disengaged and the clutch for even gears engaged.

Depending on the car and the setup, the gear change can take anywhere from 10 to 200 milliseconds, which is significantly faster than a human could manage.

When a DCT is tuned for quicker changes, some find the shifts a tad too jerky at low speeds.

Fast shift times have seen DCTs used in high-performance vehicles, including the Bugatti Veyron and Chiron, but further down the food chain they’ve also been employed as a sportier and more efficient alternative to a torque converter automatic.

The have been reliability issues with some dual-clutch transmissions, most famously those fitted to the third-generation Ford Focus.

Despite the similar name, the Speedshift MCT (multi-clutch transmission) in the Mercedes-AMG 63 models is not a dual-clutch design, but rather a traditional automatic design which uses a multi-clutch assembly instead of a torque converter.

Also known as: DSG (Volkswagen, Skoda), PDK (Porsche), S Tronic (Audi), Powershift (Ford).

In the last decade or so, automatic transmissions have gone from sporting five forward gears to seven, eight, nine or 10.

With more ratios, the engine can be kept closer to its sweet spot for the current driving situation.

Despite the extra complexity and weight the extra ratios bring, these issues are often offset by improved fuel economy and performance.

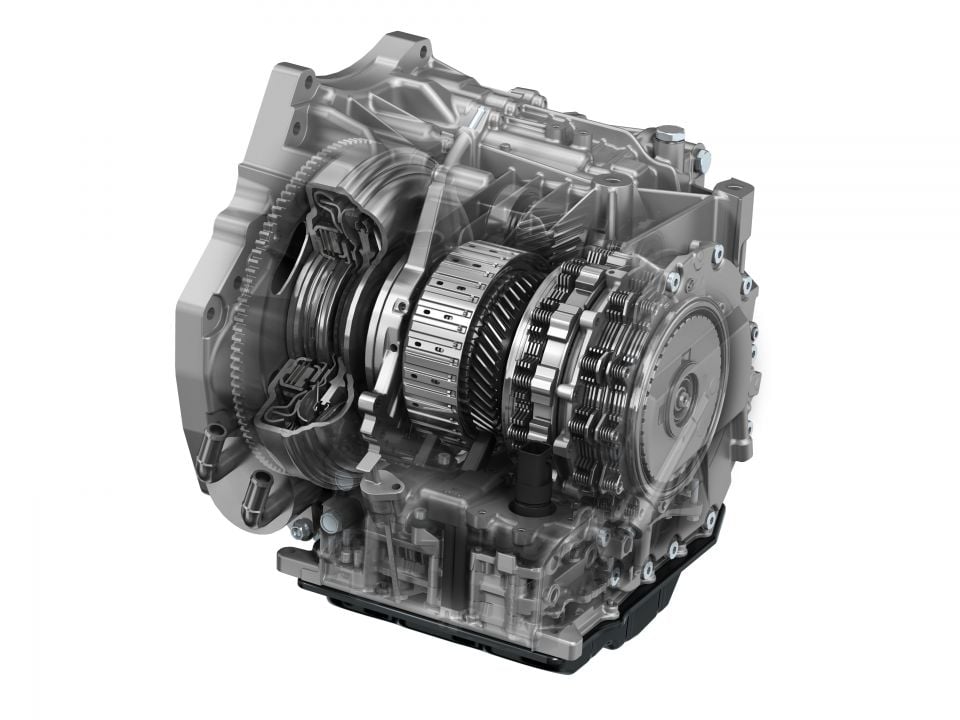

Taking this logic to its inevitable conclusion, an infinite number of gear ratios should be the most fuel efficient setup for a car with an internal combustion engine. And this is what a continuously variable transmission (CVT) aims to provide.

When the car’s in motion, the transmissions electronics constantly alters its gear ratio so the engine is sitting at the right spot in its rev range for the driving situation, whether it’s coasting, accelerating gently or pedal to the metal.

In leisurely driving or at low speeds, a CVT works perfectly fine. Under moderate or hard acceleration the engine speed rises quickly and then sits at a chosen rpm – say, 4500rpm until you lift off the accelerator.

This constant droning noise, which sounds like a slipping clutch, is annoying to enthusiasts. It also makes CVTs seem slower than they actually are because we’re deprived of the usual aural cue of hearing the revs rise, suddenly fall on a gear change, and rise again.

To counter these criticisms, some automakers have started to make their CVT behave more like other automated transmissions. While these changes give the car a better sonic experience, they chip away at the performance and fuel economy benefits of this transmission type.

As part of this movement, Toyota has even introduced a separate first gear in its latest CVT units.

While all CVTs offer a low gear for faster acceleration and engine braking, some also offer a number of driver-selectable virtual gears that can be ‘selected’ using paddle shifters.

There are many CVT designs. The most common has a V-shaped belt connected to at one end to a pulley driven by the engine, and at the other to the wheels. By adjusting the ride height of the belt, the CVT is able to change the gear ratio.

Another type of CVT is found in Toyota’s hybrid vehicles. This e-CVT system features two electric motors and the petrol engine on different points of a planetary gear set.

The larger electric motor is responsible for driving the wheels, while the smaller one restarts the petrol engine and acts as a generator to recharge the batteries.

Also known as: Lineartronic (Subaru), Xtronic (Nissan, Renault), Multitronic (Volkswagen, Audi), IVT (Hyundai, Kia)

Derek Fung would love to tell you about his multiple degrees, but he's too busy writing up some news right now. In his spare time Derek loves chasing automotive rabbits down the hole. Based in New York, New York, Derek loves to travel and is very much a window not an aisle person.

Jack Quick

8.4

6 Days Ago

Matt Campbell

8.1

5 Days Ago

Max Davies

8

3 Days Ago

James Wong

8.1

2 Days Ago

James Fossdyke

2 Days Ago

CarExpert.com.au

1 Day Ago