Damion Smy

Holden sales record as HSV sells for $1.2 million

4 Minutes Ago

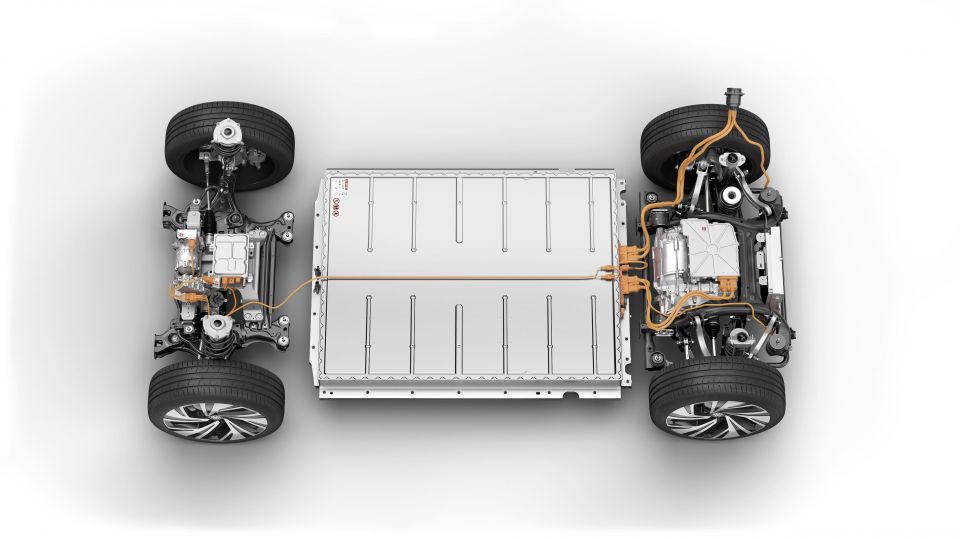

Volkswagen and Umicore have formed a joint venture to create a more sustainable battery supply chain which should see more cost-effective, reliable EV battery supply in Europe.

Contributor

Contributor

The Volkswagen Group’s new European battery joint venture aims to produce batteries for 2.2 million electric vehicles (EVs) by 2030.

Newly christened Ionway, the AU$4.5 billion joint venture between Volkswagen’s battery subsidiary, PowerCo, and circular material technology company, Umicore was first announced back in 2021.

Based in Brussels, the joint venture will see Umicore supply Volkswagen with the cathode materials needed for EV batteries.

Volkswagen has set ambitious goals for the partnership, stating that Ionway aims to reach an annual production capacity of 160 gigawatt hours (GWh) a year by 2030.

Progress towards this goal will start in 2025, when Ionway aims to produce 20GWh for the Volkswagen ‘gigafactory’ in Salzgitter, Germany.

Two other Volkswagen gigafactories have confirmed locations: Valencia in Spain and St. Thomas in Canada.

Volkswagen says this ‘first-of-its-kind partnership’ is intended to aid the Volkswagen Group in its transition to electric mobility, particularly in Europe, while maintaining a sustainable and transparent battery supply chain.

Ensuring a reliable and sustainable supply of cathode materials is just one part of Volkswagen’s battery supply chain strategy, which it will bolster by building six battery factories across Europe by 2030.

Speaking on the impact of more readily available, cost-competitive battery cells, Ionway CEO Thomas Jansseune said, “The foundation of Ionway sends a strong signal for the roll-out of battery cell technology in Europe.”

“We believe this company will provide some important building blocks in helping the European Union to achieve its Green Deal ambitions.”

As part of the Green Deal, the sale of new combustion-powered vehicles will be banned from 2035.

An exemption will be made for cars running on e-fuels, thanks to pushback from Germany.

In addition to its partnership with Umicore, Volkswagen has also entered a long-term agreement with Vulcan Energy Resources regarding the supply of CO2-neutral lithium hydroxide, and invested in US battery startup 24M to industrialise its lithium-ion cell manufacturing process and platform.

Only last week, Volkswagen confirmed that its flagship electric cars will no longer be getting a dedicated factory.

Instead, the manufacturer has detailed a revised strategy for its German production facilities through 2028, aimed at reducing complexity and increasing efficiency.

This means that models such as the Trinity electric flagship and upcoming electric Mk9 Golf will be produced at the existing Zwickau plant, which currently produces MEB-based electric models including the Volkswagen ID.3, ID.4, and ID.5, as well as the Cupra Born, and Audi Q4 e-tron.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Damion Smy

4 Minutes Ago

Josh Nevett

14 Minutes Ago

Max Davies

44 Minutes Ago

Derek Fung

2 Hours Ago

Max Davies

8 Hours Ago

Damion Smy

16 Hours Ago