Despite all the worldwide Dieselgate controversy and emissions cheating by carmakers, diesel remains a commonly-used fuel.

The better highway fuel economy offered by diesel engines coupled with their ability to produce lots of torque at low revs means it remains a viable option for those who drive long distances regularly, or need to do a lot of towing.

As its name suggests, biodiesel aims to replicate the characteristics and usability of normal diesel fuel using components that are more environmentally friendly.

Biodiesel can be used as a fuel on its own or in a blend, where it is mixed with standard diesel fuel at varying proportions. In Australia, biodiesel blends are available as B5 or B20, containing 5 per cent and 20 per cent biodiesel respectively.

How biodiesel is made

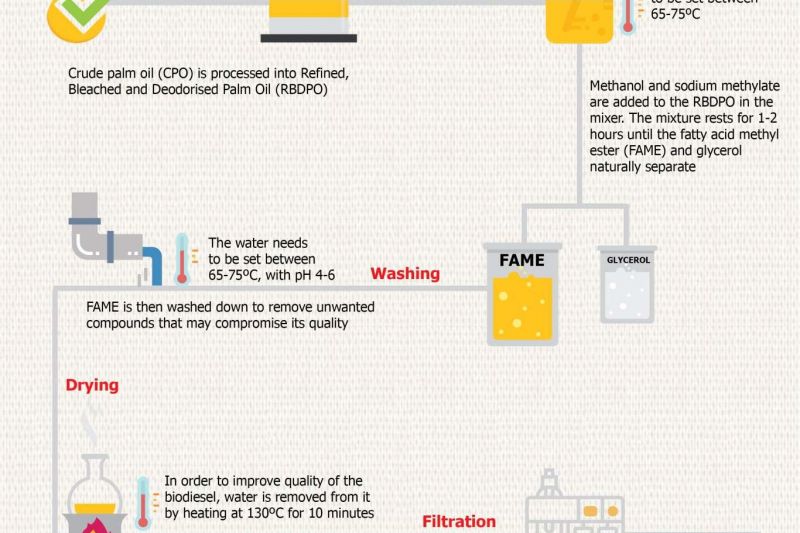

Unlike standard diesel, biodiesel is produced from renewable, biodegradable sources. It is made by reacting fatty acids that are insoluble in water, known as lipids. This means that a variety of lipid-rich sources can be used to make biodiesel, including a combination of animal fats, soybean oil, various other vegetable oils, or even the leftover grease found in restaurants.

These sources are all combined and converted to biodiesel through a process known as transesterification. Once water is removed from the sources described above, they are combined with ‘short chain’ alcohols (typically methanol) and a catalyst (usually sodium or potassium hydroxide).

The subsequent reaction produces methyl esters (biodiesel) and glycerine at a ratio of 10:1 – with the glycerine by-product having other uses in the manufacture of cosmetic goods and various pharmaceuticals.

Biodiesel is different from the similarly-named fuel known specifically as renewable diesel. Renewable diesel is produced from the same sources as biodiesel described above, however rather than relying on transesterification it’s refined in a process that involves the application of heat and high pressures, known as hydrogenation.

Renewable diesel is a relatively new development compared to biodiesel, and not yet widely available.

Benefits and disadvantages of biodiesel

One of the key benefits of biodiesel is its usability as a drop-in substitute for standard petroleum-based diesel. Older injection pump diesel engines can typically use pure biodiesel without modification, whilst newer common-rail diesel engines can accept biodiesel blends of up to B5 (some can also accept B20) without issue.

Be sure to check with your manufacturer as to the proportion of biodiesel that your vehicle can accept. In Australia, the ACCC requires diesel fuel containing more than 5 per cent biodiesel to be clearly labelled at the service station.

As a renewable fuel that can be produced from readily available waste materials, biodiesel carries obvious environmental benefits in its production compared to standard diesel. Additionally, the burning of biodiesel produces lower levels of CO2 than its standard counterpart.

This includes biodiesel blends, with even a B20 blend claimed to reduce carbon dioxide emissions by 15 per cent according to the US Department of Energy.

The primary disadvantages of biodiesel relate to its performance and operability at low temperatures. Filling a car with pure biodiesel may reduce power by approximately 10 per cent, whilst the lower energy content of biodiesel also means that the actual fuel consumption could be comparatively higher than standard diesel.

In very cold conditions, there is also a risk that some of the compounds within the fuel may crystallise, rendering your car inoperable.

Other biofuels

Perhaps the most interesting but niche biofuel is the white wine blend used by Prince Charles for his Aston Martin DB6 Volante.

Powered by a mix of discarded wine and whey (a byproduct of cheese production), the combination forms a type of bio-ethanol to which 15 per cent unleaded petrol is added. This effectively means the Aston Martin is powered by E85, and as discussed in the previous article in this series, carries all the associated performance benefits with it.

Another sustainable fuel that has seen some usage recently is pure plant oil (PPO). This is simply unmodified vegetable oil, and certain diesel engines have been successfully converted to run on vegetable oils such as rapeseed.

However, the use of PPO may harm the long-term durability of engine and also affect operability at low temperatures, due to the risk of vegetable oil solidifying. Some Volkswagen TDI models are examples of cars that can be converted to run on PPO.

Methanol (a type of alcohol) is another more environmentally-friendly fuel that has found favour in scenarios such as motorsport.

Produced largely from methane (which can be sourced from natural gas), methanol fuel has a high octane rating which, similar to E85, makes it appropriate for the high compression ratio engines used in motor racing. Methanol brings with other safety benefits.

Unlike petrol or diesel fires, methanol fires can be extinguished using water. Additionally, methanol burns invisibly without producing smoke or a visible flame, thereby reducing the chances of drivers having an impaired view in the event of a collision (although of course, this also makes detection of the fire harder in the first place).

Methanol has been used as a racing fuel in competitions such as Monster Trucks, various drag racing events and previously in the IndyCar competition.