The hand-built, one-off concept has been revealed, and dazzled onlookers with its stunning design and technology. Potential customers love it, the press is begging the carmaker to make a production version, and dealerships want it on the lot as soon as possible.

What happens next? Now begins the long process of actually engineering and developing the production version of the concept, the car customers will eventually buy.

The key challenge is being able to translate the themes and design presented in the concept car into a vehicle that can not only be profitably mass-produced, but is also safe, reliable, and durable enough to work in a variety of climates.

The development and engineering process can be split into two phases – the actual development of the car itself (product engineering) and how to build the car (manufacturing engineering).

The process of building the car includes selecting the right factory, getting suitable equipment (such as robots and other tools) onto the production line that can make the car without defects, and choosing the best suppliers to provide various parts of the car.

While car development might kick off with developing the car itself, there is a lot of overlap between phases. For example, the team devising a way to ensure robots get the right curve on a body panel might interact with a product engineering team to make sure it’s feasible.

The latest Bentley Continental GT, for example, utilises a new “Super Formed” process to make those curved haunches – this would have required a lot of collaboration between teams that were developing the car, and teams that were developing a process to build it.

Typically, devising a process to build the car will ramp up as the engineering and development activities around the car itself are completed.

Developing the car itself

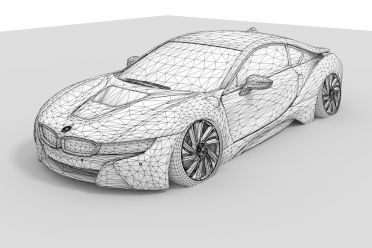

In today’s digital age, product engineering generally begins with digital development of a car. Computer programs are used to create a virtual 3D model (a process known in industry lingo as CAD – computer aided design).

Following this, designers produce scaled and full-size models of the car in clay. This gives designers a better sense of vehicle proportion and size, and helps facilitate the final design of the production car.

Next comes a series of prototype vehicles that are usually hand-built. Those heavily camouflaged photos of new models that are often seen on automotive websites? They’re usually spy shots of these engineering prototypes.

Why bother with camouflage? Carmakers don’t want to spoil the final design for customers, nor do they want to create a bad impression by driving around in an unfinished vehicle someone might mistake for a finished vehicle. On the other hand, camouflaging a car in swirls and other weird shapes only attracts more attention to it…

Sometimes with a very early prototype, the carmaker may only want to test a particular component of the car such as its chassis, which means the body is often roughly made by cutting up pieces of other vehicles to completely disguise the final design.

This occurred perhaps most famously during the development of the new C8 Corvette, where General Motors stretched the body of a Holden Commodore Ute over the mid-engine Corvette chassis to hide its design.

Some carmakers can afford wind tunnels to test the aerodynamics of a car, as well as other facilities that can simulate various weather conditions, such as water crossings. Prototype vehicles undergo all of this simulated testing, but there’s nothing quite like the real deal, so these camouflaged vehicles undergo real-world durability testing.

One of the most popular locations to test vehicles in cold conditions is Arjeplog, Sweden. Around 100km south of the Arctic Circle, brands ranging from BMW to Fiat have established testing centres, taking advantages of the fact temperatures from January to March often drop to -40oC.

The icy conditions also mean the site is a perfect test-bed to assess the performance of all-wheel drive and stability control systems.

On the other end of the scale, Death Valley in California is one of the hottest places on Earth – it recently hit 54.4oC. These temperatures make it an ideal location to undertake hot-weather testing to determine how well features such as the air-conditioning can handle the heat.

Depending on the vehicle, other types of testing conducted with prototypes could include track testing at locations such as the famous Nürburgring in Germany.

Once prototype testing with camouflaged vehicles is complete, development moves into the pre-production stage. A pre-production car is analogous to beta software. It resembles the final car that will be sold, but the build quality might be substandard or some parts of the interior may not be up to final production quality.

When cars are offered to journalists for a ‘first drive’ or when the production model is shown at a motor show, it is typically a pre-production model that is actually demonstrated.

Pre-production cars are used to expose any final problems with the vehicles or to determine whether any additional tuning or refinement (e.g. the firmness of the suspension, steering feel etc.) is needed.

This is also the stage at which manufacturing planning really kicks in – with pre-production vehicles used to test how well the car can be built.

Developing a process to build the car

This phase begins in parallel with the actual development of the car, but may ramp up when the actual car development work nears completion. Teams that devise a way to build a car might not receive the same limelight as those who engineer the car itself, but their work is just as important.

It is during this phase when key practical decisions are made, such as which robots and equipment will need to be installed on the production line. The sequential process of making the car in a way that is efficient, with minimal wastage of raw materials, is also developed during this time.

Other factors that could taken into account during this stage include the proximity of suppliers when deciding what factories will build the car, and ensuring that the overall process of making the car is as cost-effective as possible.

Once both vehicle development and the process to build the car has been completed, the vehicle is ready for mass-production.