Major supplier ZF has released a concept vehicle based on the Porsche Taycan, made to show off the next-generation EV drivetrain it will sell to carmakers from 2026.

The company – best known for its automatic transmissions – claims its EVbeat concept sets standards for compactness, lightweight design, and energy efficiency. That’s important because putting bigger batteries into long-range electric cars is hardly an efficient tactic to add range.

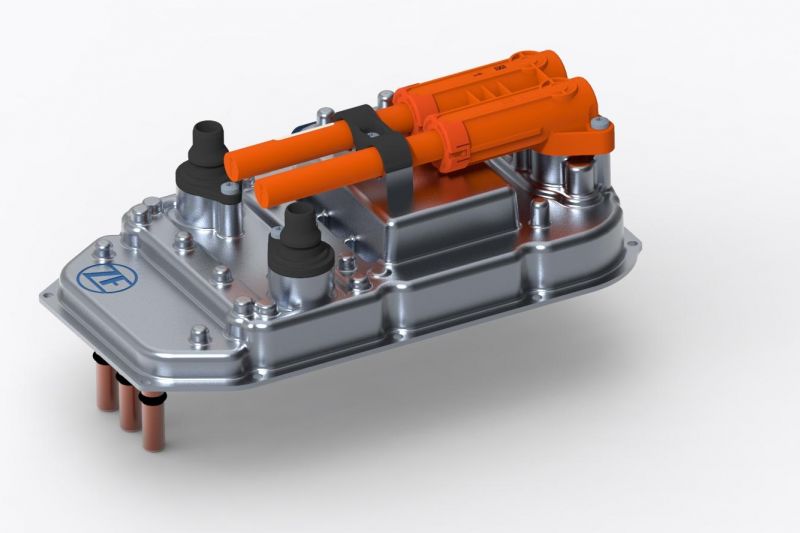

ZF’s ‘EVSys800’ drive system comprises an 800V electric architecture to allow rapid DC charging, but adds new silicon carbide power electronics, and a newly developed e-motor and reduction gearbox. Power from the motor is 275kW peak, or 206kW continuous.

This drive system sans battery weighs 74kg, which is 40kg lighter than ZF’s current 800V series drive system when making the same outputs, the company says.

A newly patented form of electric motor winding saves space and cuts copper use, helping minimise cost, and there’s a new cooling method – oil flows directly around the copper rods – that potentially allows more performance in a smaller installation space.

Meanwhile the inverter has been “fundamentally redesigned” as well, with ZF claiming “significant improvements” to things like electromagnetic compatibility, and the packaging of power modules and capacitors.

A new coaxial reduction gearbox transmits motor drive via two planetary gear sets that generate the desired final drive ratio, and perform an integrated differential function. This makes the off-the-shelf product easier to package, ZF claims.

“With this system, we can perfectly meet the main requirements of our customers – namely efficiency, performance and costs,” said ZF head of development for electric driveline systems, Otmar Scharrer.

“In terms of torque density, we are at the top of the podium when we compare ourselves with e-drives for passenger cars currently available on the market. At the same time, we paid strong attention to the sustainability aspect during development.”

The electric motor works without heavy rare earths and the thermal management system does not use fluorine-based coolant. The reduced number of components and the overall 30 per cent reduction in system weight is pitched as a double bonus.

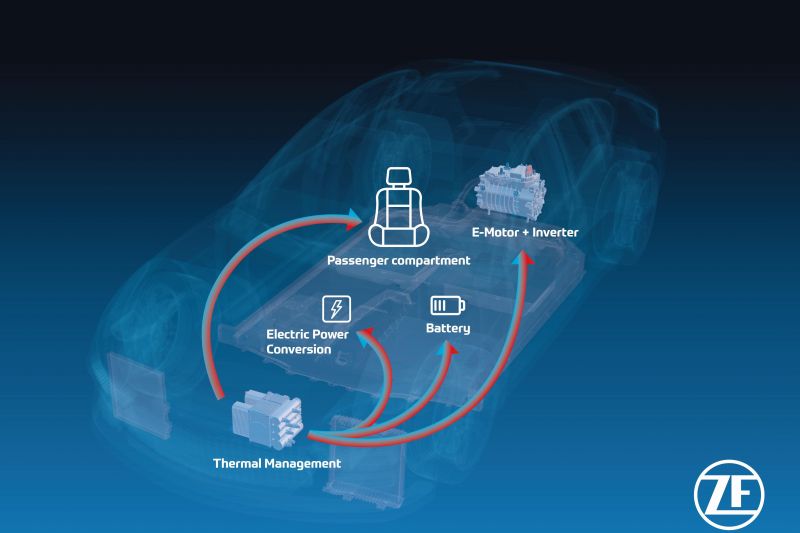

Another area of focus was the thermal management system with three designated circuits, which was designed in large part to cut the amount of energy sucked out of the battery on cold winter days.

A central unit and software control all thermal processes for the driveline and passenger compartment alike, while a propane-based 800V heat pump should use significantly less energy.

Indeed, ZF claims the battery range increases by up to a third in “demanding winter operation”, while at the other end of the spectrum the significantly better cooling performance makes the higher continuous output of the e-machine possible.

On the software front ZF developed its own powertrain coding that networks all vehicle systems with each other and establishes connection to the cloud.

The driveline software can also anticipate optimum operating points from individual driving profiles and prime the system accordingly. It ‘learns’ the behaviour of drivers and can anticipate probabilities through an AI-based cloud service. Spooky.