I do love a cool MX-5 engine swap, but this time it’s not just any old conversion. Instead, it’s a so-called “one-stroke” engine concept developed by Spanish developers, INNengine.

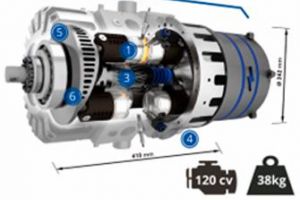

In a world where weight savings are paramount, this compact powerhouse could be just what the doctor (engineer?) ordered. Weighing in at 35kg, this pocket-sized engine boasts a claimed output of 90kW (120hp) and 244Nm of torque.

Although originally designed as a range extender for electric vehicles or a direct power source for drones, aircraft, and portable generators, the creators of this innovative engine went a step further.

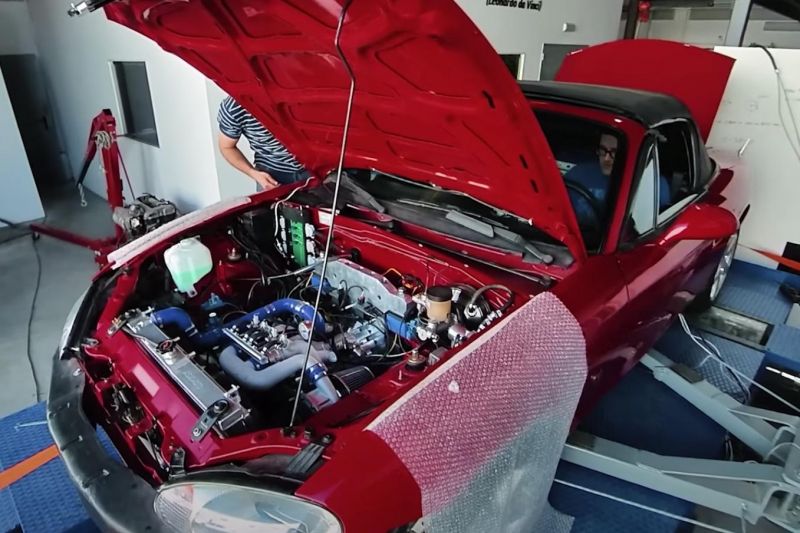

They tackled the age-old question: “Will this fit in my Mazda?”. The resounding answer is ‘yes.’ They took their prototype engine and dropped it into a Mazda MX-5, just to prove its versatility.

But first, let’s explore what sets this creation apart from a regular in-line or ‘vee’ configuration engine.

While INNengine refers to its engine as a “one-stroke” design, it’s important to note it actually operates on a two-stroke combustion cycle.

Unlike traditional two-stroke engines though, the INNengine eliminates the need for oil in the fuel mixture, or using one stroke for lubrication or cooling purposes.

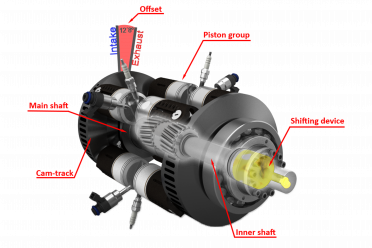

Fuel lubrication is not the only thing this engine does without. It has no crank, no valves, no camshaft, and no connecting rods. Instead, it boasts twice as many pistons as it does cylinders.

The engine features a unique opposed-piston configuration with four pistons on each side, totaling eight pistons. These opposing pistons share a common combustion chamber and are connected to fixed rods.

Instead of using traditional connecting rods, the pistons sit on rollers riding against a lobed circular plate, which is commonly referred to as a ‘swashplate’ design. This configuration not only allows for adjustable timing but also an adjustable compression ratio, making it one of the coolest features of the design.

During operation, as the lobed circular plate reaches its peak, the pistons move towards the top-dead-centre position.

At this moment, fuel is directly injected into the cylinder, and a spark plug ignites the compressed air-fuel mixture, providing the engine’s power output.

The engine achieves intake and exhaust processes similar to a two-stroke engine, with the exhaust port opening just before the intake port, creating a scavenging effect. The synchronised motion of the pistons in each cylinder bank allows for efficient intake and expulsion of exhaust gases.

It’s worth noting the term “one-stroke” is used by INNengine due to its catchy nature. In reality, the engine follows a two-stroke combustion cycle.

However, by avoiding oil in the fuel mixture and incorporating efficient intake and exhaust processes, INNengine’s engine overcomes the emissions and lubrication drawbacks associated with traditional two-stroke engines.

While it may not truly be a “one-stroke” engine in the conventional sense, the INNengine’s unique design and optimised combustion cycle offer significant advantages in terms of power, efficiency, and emissions compared to traditional engines.

INNengine’s creation, if it can live up to their claims, packs numerous advantages.

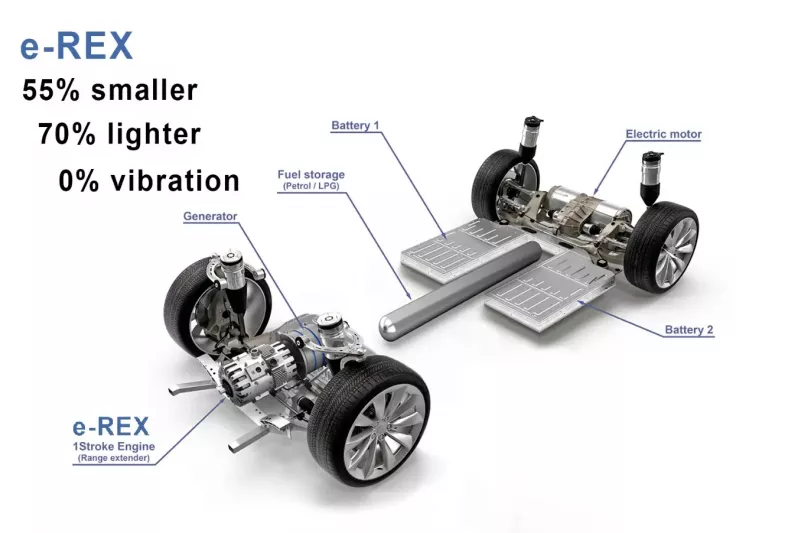

Firstly, its compact size makes it a great fit for lightweight vehicles, drones, and small aircraft. Measuring 260mm by 420mm, they claim it’s 70 per cent smaller and lighter, using 60 per cent fewer components, resulting in improved balance, less vibration, and noise reduction.

Additionally, the engine can be set up run on regular petrol or hydrogen, adding to its versatility.

The primary focus for INNengine is on the electric vehicle (EV) segment as a range extender. The engine would operate as a generator, disconnected from the drivetrain, boosting efficiency and extending the range of EVs.

This could potentially reduce the requirement for bulky batteries, while still providing the driver with the ability to refuel at regular service stations.

Although INNengine has only recently come to the attention of the general public following a successful crowdfunding campaign that has raised over $2,000,000, the project has been in development for over a decade.

Every so often, we come across startups showcasing axial and swashplate engine layouts that promise great potential but struggle to break into the mainstream.

INNengine joins this intriguing line-up, and only time will reveal if it has what it takes to make an impact.

Considering the stringent certification requirements of the aviation sector, it’s hard not to think that the most exciting application for this engine might just be in that humble Miata.