Australians are well known for being an outdoorsy bunch, and for many the best way of transporting that boat, horse float or caravan is to hitch it up to a car and tow it.

The wide variety of things that we like to tow, and the different environments that we like to tow them through, has correspondingly resulted in a booming hitch and towbar market.

Today, a variety of products are available to make that long weekend or those Easter or Christmas holidays a stress-free experience, even in rough terrains.

Nevertheless, before attaching that trailer to your vehicle, there are a number of important weights and measures to take stock of…

Useful definitions

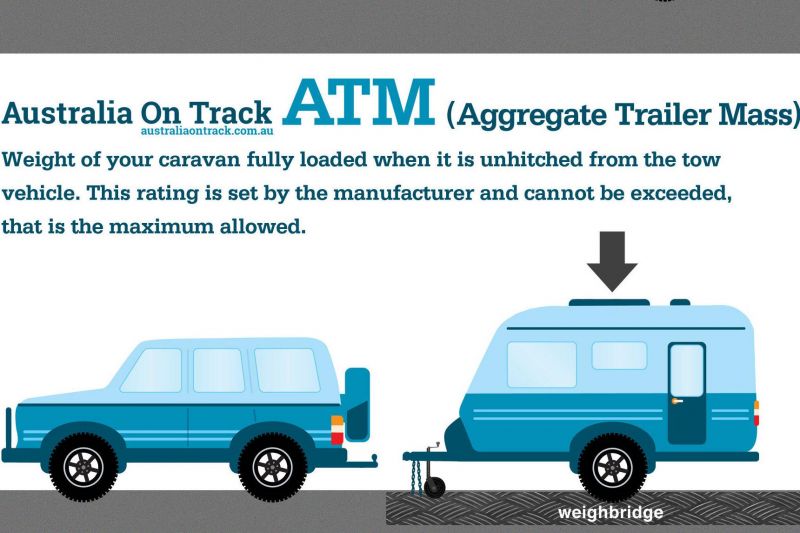

The most fundamental capacity to take note of when towing is how much the trailer can carry, or its payload capacity. The combination of maximum payload capacity with the actual tare (unladen) weight of the trailer is known as the aggregate trailer mass (ATM).

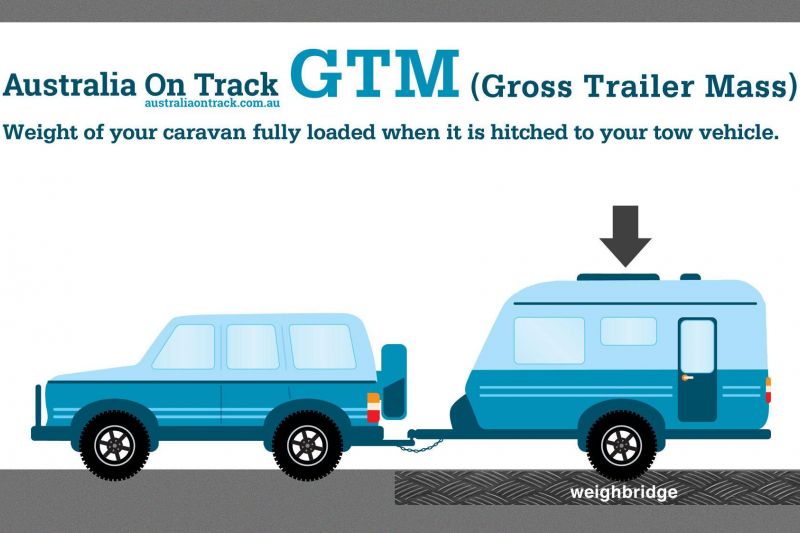

Note that the ATM is often confused with GTM (gross trailer mass), which refers to the weight transferred to the ground via the trailer’s wheels, which in most cases is lower than the ATM. This is because part of the gross trailer mass is transferred to the towing vehicle when coupled.

ATM subsequently forms the basis of calculations for a vehicle’s braked and unbraked towing capacity. Braked towing capacity refers to the aggregate trailer mass (ATM) of a trailer which uses its own brakes, and is usually significantly greater than a vehicle’s unbraked towing capacity, which refers to the maximum ATM of a trailer without brakes that a vehicle can tow.

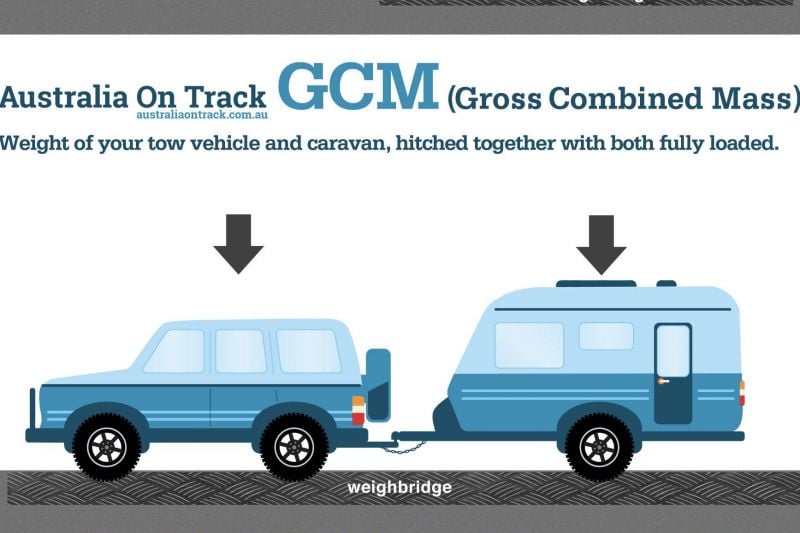

On long adventures, it’s often not just the trailer that is fully loaded, but also the towing vehicle, filled as it is with family, friends, fuel and everyone’s gear. The ATM combined with the Gross Vehicle Mass (maximum weight a vehicle can handle) forms the GCM, or Gross Combined Mass. When coupling a trailer, it is important to ensure this limit is not exceeded.

Of course, the towbar and associated coupling must be able to withstand a significant amount of force. Towbars therefore have their own limited weight rating that restricts what they can haul.

If the ATM exceeds this rating, it will be unsafe to tow a trailer regardless of the towing vehicle’s braked or unbraked towing capacity. Additionally, consideration must also be given to the trailer ball load, also known as the downball weight or tow ball load. This refers to the maximum vertical weight that can be applied on the tow ball.

Going beyond this limit may compromise the towing vehicle’s ability to properly steer and brake.

Types of towbars

Towbars come in a variety of shapes and sizes, however there are four popular designs that together cater for the vast majority of use cases and environments.

A flat tongue towbar is a simpler design best suited for towing lighter loads. The curved ‘drop tongue’ includes a tow ball hole, offering space for a detachable tow ball. The other side of this design features a square metal tube known as the ‘shank’, which enables this design to connect to a hitch which in most cases, is built into the underside of your vehicle.

A horizontal hitch towbar is a more heavy-duty design suitable for towing larger loads. These are generally a multi-piece setup, and include a horizontal frame that mounts to the underside of the car. The horizontal frame section is often designed to specifically fit the factory mounting points on your car, so be sure to purchase a version tailored to your vehicle.

The frame section incorporates either a square 40mm or 50mm receiver hitch, with the 50mm version offering greater towing capacity. Additionally, a separate ball mount that connects to the receiver hitch is also included, facilitating use of a tow ball.

If you are looking to tow in rough terrain or off-road, the best option might be a rear step towbar. These designs protrude significantly from the rear of the vehicle, offering a form of sacrificial protection for the rear bumper.

Moreover, the incorporation of a step not only creates an elevated design to maximise ground clearance, but also offers easier access to the roof of the car, in the event an item is also being stored on roof racks.

Many European cars may come with a ‘swan neck’ towbar. This design is permanently attached to the vehicle (although some brands such as BMW offer retractable versions that stay out of sight when not in use), and consist of a vertical, upward sloping tube much like the neck of a swan.

Although more elegant in design than the other models described here, these models may offer reduced towing capacities similar to a flat tongue towbar.

Towbar classes

Apart from the towbar design, an important consideration is the maximum weight it can tow. This capacity must exceed or match the vehicle’s braked or unbraked towing capacity in order to maximise towing ability. Today, towbars fall into three distinct classes.

Class 2, also known as light-duty towbars, are rated to a maximum of 1200kg and are therefore suitable to tow lighter items such as a small trailer. Most flat tongue towbars fall into this category.

Class 3, or medium-duty, towbars are rated to tow up to 1600kg, suitable for medium sized trailers. Entry level horizontal hitch towbars would fall into the Class 3 category.

Heavy-duty towbars fall into the Class 4 category, and are typically rated to tow up to 3500kg, suitable for a large caravan. Stronger horizontal hitch or rear step towbars are likely to be categorised within this class.

Hitches – another essential component

Towbars need another mechanism to connect to a trailer or other cargo, and this is typically known as a hitch.

The most common type of hitch is the standard 50mm tow ball connected to a rigid ball mount. The universality of this option in Australia makes it easy to connect a wide variety of trailers, caravans and other items to the towbar types described above.

A rigid 50mm towball is ideal for towing on asphalt surfaces, as long as the towing vehicle is being driven cautiously and at low speeds through sharp turns.

Articulating hitches (also known as off-road couplings), in contrast, are best suited for rough terrain as the hitch can rotate up to a full 360 degrees. This may act as an important safety feature by allowing the trailer to roll independently of the towing vehicle.

Weight distribution hitches are a more sophisticated option, and may be especially handy if the cargo being towed is approaching the limit of the towbar’s (or towing vehicle’s) weight capacity.

These hitches typically use a combination of round or trunnion spring bars connected to a system of chains, to ensure weight is distributed evenly between the towing vehicle and trailer.

In turn, this prevents any squatting or diving from the towing vehicle or trailer respectively, thereby ensuring that the cargo can be towed safely with minimal compromise to the vehicle’s braking or steering ability.

MORE: We have pages of these technical explainer articles, all located here