Mazda is a much smaller company globally than fellow Japanese brands Toyota, Nissan and Honda but it has a storied history, being initially founded as a cork factory in 1920 before switching to vehicle production in 1931.

Arguably more so than its Japanese counterparts, Mazda is unafraid of taking risks. Some of these, such as the development of the MX-5, have paid off.

Others, such as the continual investment in rotary engines, have been less successful, despite producing some iconic cars. Some have even brought the company close to bankruptcy, such as its over-investment in the Amati and Eunos luxury marques during the height of the Japanese economic boom in the 80s and early 90s.

Mazda’s most recent long-term gamble has been the development of a new approach to making more efficient cars without compromising on performance, or the lauded ‘Zoom-Zoom’ and ‘jinba-ittai’ (unity of rider with horse) driving feeling that Mazda claims its cars are renowned for.

This approach is known as SkyActiv, and represents a suite of technologies ranging from engines to transmissions and chassis technologies.

Brief history

Elements of Mazda’s SkyActiv philosophy have been in production for more than a decade, and the first car to be sold in Australia under the SkyActiv banner was the BL Series 2 (mid-life facelift) Mazda 3 hatch and sedan introduced in late 2011.

These models were equipped with SkyActiv engines and transmissions only, and while the power and torque increases of the 2.0-litre SkyActiv-G engine were modest compared to the preceding MZR 2.0-litre engine, the cars did have a substantial 25.6 per cent improvement in fuel consumption.

Today, the entire Mazda passenger car and SUV range makes use of the full gamut of SkyActiv technologies. The one exception is Mazda’s BT-50 ute, based on the Isuzu D-Max. However, Mazda claims that, as the latest BT-50 features significantly more economical engines than its predecessor, it aligns with the overall SkyActiv philosophy.

It’s important to note that while Mazdas on sale today share SkyActiv branding with models sold a decade ago, this doesn’t mean that Mazda has been standing still, with Mazda regularly improving and refining SkyActiv technology.

SkyActiv engines

Mazda’s SkyActiv engine family can best be thought of as a series of engineering principles and shared design elements, that span a wide variety of naturally aspirated, turbocharged (both petrol and diesel) and hybrid powertrains.

These include comparatively high compression ratios for petrol engines, and comparatively low compression ratios for diesel engines.

Mazda claims that for petrol engines, a high compression ratio improves thermal efficiency, leading to greater fuel economy, whilst also improving low and mid-range torque for better everyday drivability.

Mazda’s naturally-aspirated petrol SkyActiv engines therefore generally use high compression ratios ranging from 13.0:1 to 15.0:1 in the innovative SkyActiv-X powertrain, while even turbocharged petrol SkyActiv engines adopt a 10.5:1 compression ratio, high compared to similar powerplants.

One of the risks with using high-compression ratios is an increased risk of engine knock, whereby the air-fuel mixture combusts prematurely, and can cause serious damage to the engine.

One common solution to this is limiting the engine to only accept high-octane fuel (such as 98 RON), however, Mazda has designed a more permanent alternative by adopting a ‘4-2-1’ exhaust system. This physically increases the length of the exhaust manifold, and lowers the chances of hot residual gas being forced back into the combustion chamber and inducing engine knock.

For diesel engines, a low 14.0:1 compression ratio is used, which Mazda claims allows its engines to meet stringent Euro 6 emissions regulations (especially relating to nitrous oxide or NOx emissions) without the need for AdBlue or other exhaust gas treatments.

Recently, SkyActiv technology has moved into the mild-hybrid space, with the e-SkyActiv G engine making use of a 24V mild-hybrid system to improve fuel economy.

Perhaps the most notable innovation in the SkyActiv engine lineup, however, has been the introduction of the SkyActiv-X engine. Mazda claims that this engine combines the best aspects of petrol and diesel engines through a process known as Spark Controlled Compression Ignition (SPCCI).

SPCCI combines the best elements of spark ignition, as used in petrol engines, with compression ignition, as used in diesel engines.

An initial spark is used to generate a fireball to begin the combustion process, similar to a petrol engine. However, the actual combustion of the air-fuel mixture occurs rapidly and consistently, similar to compression ignition, rather than the gradual combustion of a typical petrol engine.

Mazda claims that this technology allows it to deliver 30 per cent more torque than a standard SkyActiv G 2.0-litre engine, while also besting the SkyActiv D diesel in fuel economy.

Real-world testing of the Mazda 3 with this powertrain has shown its combined economy to be slightly better than that of the more powerful 2.5-litre engine, if not as frugal as, for example, a Toyota Corolla hybrid. It’s also offered in the related CX-30.

SkyActiv transmissions

Mazda has also applied SkyActiv principles to the transmissions it uses, including both manual and automatic transmissions.

Manual transmissions have had more than a century of refinement, yet the manual transmission in Mazda’s MX-5 is widely lauded as one of the best available in the industry regardless of price.

With its new SkyActiv-MT, Mazda aimed to replicate the shift feel of the MX-5 across manuals used throughout its lineup, facilitating a reduction in transmission weight of 16 per cent, through developments such as the removal of the reverse idle shaft.

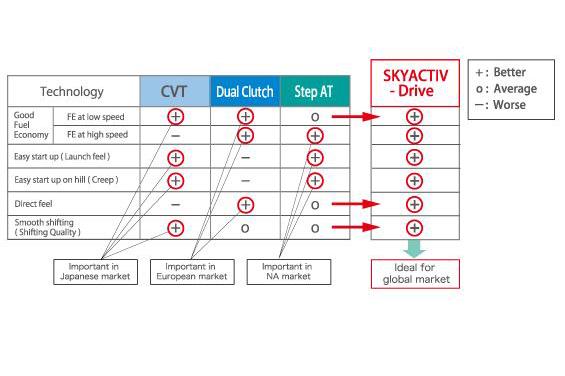

Automatic transmissions have long overtaken manuals in popularity in markets such as Australia and the US, and perhaps the more impressive development is Mazda’s SkyActiv-Drive automatic transmission, which it claims combines the best elements of standard torque converter, CVT and dual-clutch transmissions used in other vehicles.

Practically, SkyActiv-Drive works as a conventional automatic transmission. Normally, these transmissions feature a lock-up clutch that matches transmission speed to engine speed, but only operate 50 per cent of the time to maintain low levels of noise, vibration and harshness (NVH).

With its SkyActiv-Drive transmission, Mazda uses a lock-up clutch that can operate 80 per cent of the time and, with the addition of a vibration damper, doesn’t cause any loss in refinement.

Mazda claims this enables its transmission to have the smooth takeoff and creeping of a traditional automatic, with some of the responsiveness and direct driving feel of a dual-clutch, and none of the slippage or droning noises commonly experienced in CVT transmissions.

SkyActiv body and chassis

Body and chassis structures are key contributors to the weight and safety of a vehicle, and Mazda claims it has made significant improvements under its SkyActive philosophy.

The overall approach here was to coordinate the various disparate structures that are combined to form a monocoque, with a focus on load transfer and rigidity. This meant that, where possible, previously curved aspects of the monocoque would be replaced with a more rigid, straight part, while more advanced welding and bonding techniques would be used to create a continuously bonded framework.

These developments allowed Mazda to improve safety by creating a more refined multi-path load structure such that in the event of a collision, forces are distributed in multiple directions rather than through a single part of the body.

Materials-wise, Mazda claims that vehicles with a SkyActiv body also incorporate a greater proportion of high-tensile steel, bringing benefits to both body strength and weight.

While suspension and steering systems can vary based on model (e.g. the Mazda 3 uses a cheaper torsion-beam rear suspension, rather than an independent setup like the Mazda 6 and CX-5), Mazda claims it has revised its approach to suspension development, and has also introduced a new electric power steering system that offers better high-speed stability and low speed agility.

Other vehicle dynamics

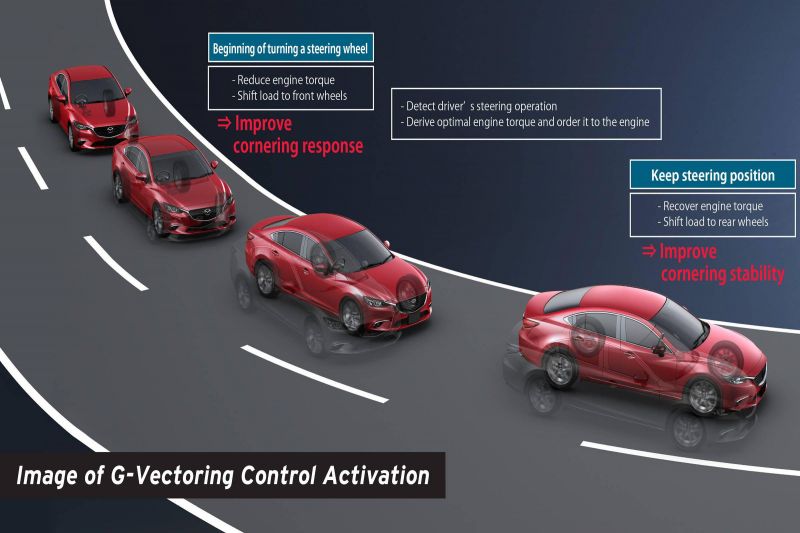

Alongside improvements to the physical body and chassis, Mazda has also introduced more advanced electronic vehicle dynamics technologies, that aim to improve cornering at speed. Known as G-Vectoring Control and G-Vectoring Control Plus (GVC and GVC Plus), these can effectively be thought of as Mazda’s take on torque vectoring.

The original GVC minutely modulated engine torque output based on the driver’s steering and acceleration inputs, aiming to manage the forces that act on the vehicle and provide subtle improvements to vehicle turn-in.

The latest system, GVC Plus, more closely mimics the brake-based torque vectoring systems used by other carmakers, in adding momentary braking, in an attempt to improve vehicle stability and enhance handling.