Max Davies

5 Days Ago

What happens to the battery in your electric vehicle when it reaches the end of its life?

Contributor

Contributor

A couple of months ago I caught an Uber into the city, and at one point in traffic there were white Teslas in front and beside us. “We’re in a Tesla Sandwich”, I said to the driver.

He replied after glancing around “I don’t know about these electric cars. Those batteries can be dangerous and when they get chucked out they’ll end up at the dump like all the others – no one recycles them”.

It’s sadly correct that in Australia across the various chemistries (with the exception of lead acid) the CSIRO found only about 3.0 per cent of batteries are captured for recycling.

For disposed lithium-ion batteries the driver was right: it has been the rubbish dump where most batteries have gone, with the CSIRO also finding in 2019 the capture figure for lithium-ion cells was just 2.0 per cent.

Given the dramatic rise in the number of lithium-ion products in general use, this entire recycling issue is becoming more important. In 2022 there will be over 10,000 tonnes of lithium-ion battery waste generated in Australia. Not only are lithium-ion cells in everything from personal audio devices and phones, they’re in power tools, electric scooters, and bikes.

We are also seeing large lithium-ion batteries for stationary storage and EVs. By 2036, Australian Government statistics indicate annually we will be generating between 130-190,000 tonnes of lithium-ion waste. Ideally all of that would be captured for recycling.

So, what is being done about battery recycling, especially in the case of lithium-ion units? Can these batteries be safely recycled, and if so how and when?

What follows examines what is being done here in Australia to increase the number of these batteries being recycled, and what you can do today to help keep them out of landfill.

While it is true historically most batteries were not recycled, those that were captured were typically incinerated or melted down and only about 30-50 per cent of it (mostly the core base metals, such as nickel and cobalt) recovered.

In recent years, with the emergence of larger numbers of expired lithium-ion batteries, the recycling issue has been examined closely and new processes have been developed to recycle more than 90 per cent of the battery.

There are several companies across the world, including one here in Australia, safely recycling batteries of all sizes. They all are using clever solutions that greatly minimise the risk of fire and other hazards.

Here’s a step-by-step breakdown of some of the relevant processes.

Discharge

Firstly, if it is not already, any power in the battery needs to be discharged.

Dusenfeld of Germany and Redwood Materials of the United States cleverly capture and use any remaining power in large batteries to help power the recycling process itself.

Alexis Georgeson, Redwood Materials VP of communications and government relations told CarExpert the company’s “proprietary technology allows us to make use of residual energy in live, end-of-life batteries and therefore requires no external energy input.”

Dismantle

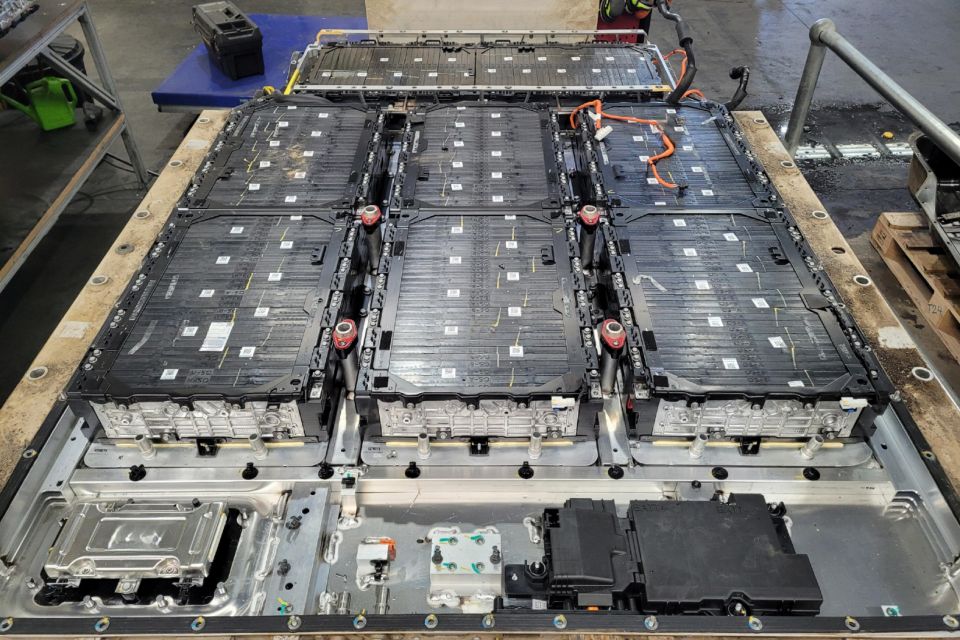

“Once safely discharged, large complex batteries require partial disassembly before shredding,” said Max Lane, commercial general manager of Envirostream.

The five-year-old Envirostream is Australia’s only fully-accredited and EPA-certified recycler of lithium-ion batteries. Mr Lane, on behalf of the Melbourne-based recycler added: “while small batteries can be shredded directly, batteries bigger than a couple of shoe boxes side by side need to be safely dismantled by hand first.”

A similar manual dismantling of large batteries is undertaken by all the other leading recyclers overseas.

Shred

The key to shredding lithium-ion batteries is the absence of oxygen. Take away oxygenated air and your chance of a fire drops remarkably.

All of today’s leading-edge recyclers utilise this step, although their methods vary. Dusenfeld shreds batteries in a deoxygenated chamber filled with inert nitrogen. US-based Li-Cycle and Australia’s Envirostream instead shred batteries in water baths.

“Most of the electrolyte is also captured in our water bath process with only a small amount evaporating and captured in our air filtration”, states Mr Lane.

Regardless of shredding method, the result is similar and afterwards, the steel, copper and aluminium found in the housings for many of the battery modules are removed. In Australia, they’re sent to local metal recyclers such as Sims Metal. The core remnant materials are then ready for the next processing step.

Further processing (black mass)

Additional refined processing and drying of the shredded batteries produces a fine black mixed metal dust the industry terms ‘black mass’.

It is composed of almost all the valuable materials the battery originally possessed such as cobalt, nickel, graphite, manganese, and lithium. This dust-like product is, after further processing and deconstruction techniques, what is used to make new lithium-ion batteries.

Envirostream presently exports its mixed metal dust to Korean firm SungEel Hitech. SungEel then takes the black mass and completes the recycling, separation, and purifying process to make new batteries.

Although the volume of lithium-ion products is increasing, there’s quite a delay before these batteries are at EOL (end of life). This is especially the case with large batteries such as found in EVs.

Tesla co-founder and Redwood Materials CEO Dr JB Straubel, said in a recent interview the EV batteries around today should have a driving life of around 15 years.

However, even when their range drops below 80 per cent of the claim when new, it does not mean they need to be ripped up, or thrown on the scrap heap.

Many are being utilised in less demanding power backup roles. In fact, consultants McKinsey & Company believe stationary storage powered by used EV batteries could exceed 200GWh per year by 2030.

This isn’t just idle speculation: there are several real-world examples already running. They include Jaguar Land Rover partnering with Pramac to develop portable zero-emission energy storage using retired Jaguar I-Pace batteries.

Another example is Audi working with German power company RWE using retired Audi e-tron batteries to provide stationary power for its 4.5MWh pumped hydro plant in Herdecke, Germany. The engineers working on the project believe the batteries should be able to provide reliable storage for 10 years after their automotive life is finished.

Predating this, Renault commenced its Advanced Battery Storage Project in 2018. It now has working battery energy storage systems in Belgium, France, and Germany, while for several years Nissan EV batteries have been graded and put to a wide range of uses, such as powering other cars and electric forklifts, as well as stationary storage.

Envirostream’s Mr Lane agrees the company won’t be flooded with EV batteries for a while.

“There are certainly more batteries coming through the gates, but organic growth will dictate our expansion plans – and high volumes of EV batteries won’t be coming until closer to 2030.”

After much planning, and partly to fix the low level of battery recycling in Australia, the Federal Government earlier this year began a Battery Stewardship program.

The Battery Stewardship Council is designed to achieve a working system of custodianship for batteries from their creation/importation through to their EOL and recycling.

The scheme is meant to put an end to the lack of responsibility of the past, where dumped batteries were allowed to leak their contents from landfill sites into waterways, and put an end to fires in kerbside collections and garbage trucks.

How Battery Stewardship works and what you can do to help

Although still in its infancy, the aim is to have a system that makes correct battery disposal and recycling accessible, convenient, and safe. There are formal collection networks, and safer battery transportation solutions.

There will also be awareness programs ensuring public and industry know how, and where, to correctly dispose of batteries. Australia’s official battery stewardship scheme is the website of the new scheme.

It’s easy to dispose of those old phone and garden tool batteries sitting in bedside drawers and sheds. Simply access the website, type in your location, and the site will show you the nearby places that accept the batteries. You also might be surprised to find some of Australia’s largest retail chains are also accredited drop-off points.

Just remember to tape the terminals before dropping batteries into these collection sites. For large batteries or commercial volumes, businesses are better off contacting the likes of Envirostream directly.

Although the Uber driver was right in pointing out most batteries end in the dump, these comments look like they won’t be true going forwards.

I couldn’t help but remind the driver, his own hybrid vehicle also had a battery that would need to be handled responsibly at EOL.

“It’ll be someone else’s car by then; that’s not my problem”, he said, displaying the sort of approach that underlines that a responsible system of battery custodianship can’t come soon enough.

Thanks to Envirostream for granting permission to use the supplied images taken at their Melbourne recycling facility.

MORE:Volkswagen-led team to recycle EV batteries multiple times MORE: Volkswagen reveals ‘BattMan’ electric car software MORE: Chinese battery giant CATL announces $6.8 billion battery recycling plant – report MORE: Used Nissan Leaf EV batteries powering Japanese train crossing

Married with two children and a pet Great Dane, my other interests include: single malt whiskies, fine rum, AFL, powerlifting, fine music and home theatre, renewable energy and last but not least - American politics. Naturally, I am also interested in cars too and have owned all three flavours: petrol, diesel and electric!

Qualifications: Geography and Environmental Science – UTAS, Political Science (Hons) - UTAS and post grad studies in Communications - QUT

Max Davies

5 Days Ago

James Wong

4 Days Ago

James Fossdyke

3 Days Ago

Gautam Sharma

2 Days Ago

Josh Nevett

24 Hours Ago

William Stopford

12 Hours Ago