Torque vectoring aims to improve steering response and handling through the distribution of torque between the wheels.

At first glance, this may seem similar to what limited-slip differentials (LSD) do. However, torque vectoring is a more advanced technology.

Perhaps the best way to differentiate the two systems is with regard to how and when they operate. An LSD is primarily a mechanical, reactive system that works in specific circumstances to limit the slip being experienced by a particular wheel, such as when accelerating or braking through a sharp corner.

In contrast, torque vectoring is a holistic, predictive approach to vehicle dynamics using a combination of hardware and electronic systems.

It provides the most suitable distribution of torque to a wheel at any point based on the driver’s intentions and the driving conditions.

Rather than purely limiting slip this could, for example, include allowing a small amount of power to be sent to a slower wheel, or proactively distributing engine power to enable the car to rotate more easily through a corner. This is known as increasing the yaw effect.

Although torque vectoring is computer-controlled, the way it operates can vary widely. Performance cars typically use a mechanical, differential-based system. More conventional vehicles incorporate a brake-based system that mimics the differential based approach.

Some cars may use a combination of the above systems to further enhance their handling.

Differential and clutch based torque vectoring

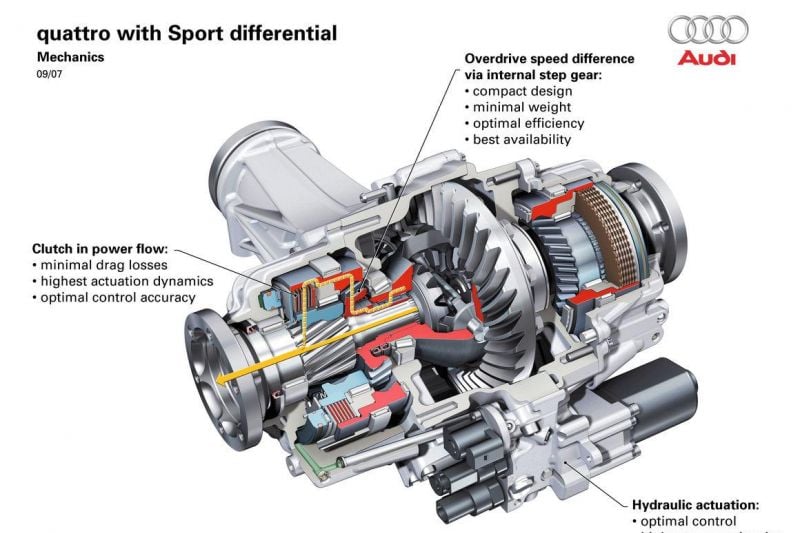

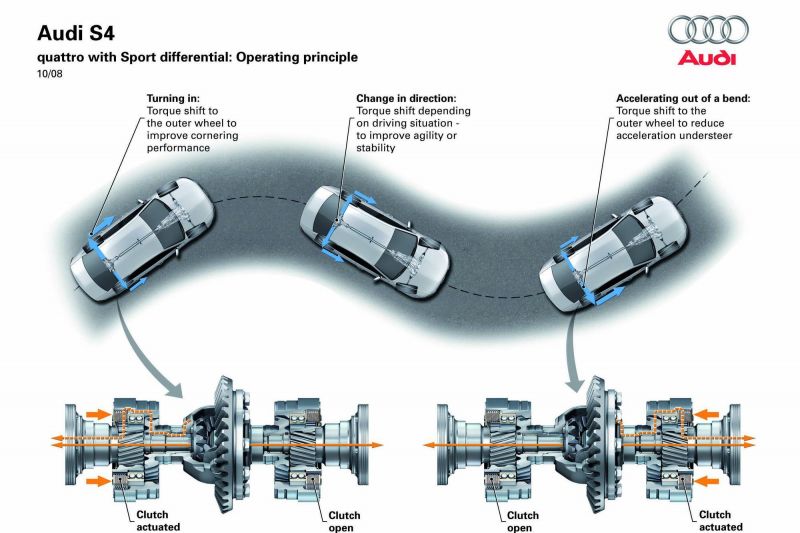

Typical differential-based torque vectoring systems combine an open differential with a pack of multi-plate clutches on either side, together with sensors measuring the wheel speed, pitch, and the yaw of the car. The clutches are not always engaged, and are instead electronically- or hydraulically actuated.

When the clutches are inactive the car functions as a conventional vehicle with an open differential, with wheels rotating at different speeds through a turn to prevent skidding.

If one (or both) of the clutch packs are active, they work to multiply or reduce the torque being directed to a wheel. In situations such as a hairpin turn, this helps the driver rotate the car by increasing the amount of torque being sent to the outside wheel.

If the car is travelling in a straight line, the clutch packs are deactivated and the car retains the characteristics of an open differential, with torque being distributed evenly between the wheels for greater stability.

Certain advanced torque vectoring systems such as the ‘Twinster’ setup on the now-superseded Ford Focus RS and the 4Matic+ system on the Mercedes-AMG A45 S, also offer a dedicated drift mode despite using an AWD drivetrain.

These systems work using a combination of two electronically controlled multi-disc clutches that are able to send a high proportion of available torque to the rear axle (up to 70 per cent in the Focus RS).

Of this torque, up to 100 per cent can then be directed to either left or right wheel to induce a slide, with the split then shifting to a 50:50 ratio between the left and right wheels to allow for a controlled drift.

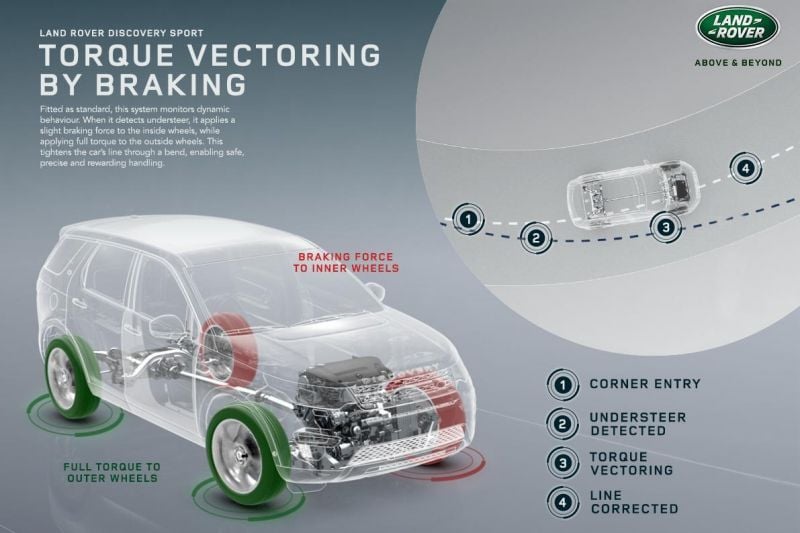

Brake-based torque vectoring

Brake-based torque vectoring is a less sophisticated system that attempts to replicate the capabilities of the mechanical system above through simpler, cheaper means. Rather than torque being shuffled through a differential, this system momentarily applies the brake to one of the wheels (e.g. the inside wheel in a turn).

The reduction in speed of the inside wheel creates a similar speed differential across the inside and outside wheels as a mechanical system, increasing yaw and helping rotate the car.

The key disadvantages of a brake-based system concern outright speed and durability. In performance applications, using the brakes to improve cornering can result in inherently slower lap times than a differential-based system.

Additionally, the use of brakes through turns over an extended period of time will cause greater wear and tear, resulting in more frequent replacement of the brake pads, or potential overheating on track days.

Brake-based systems are now commonplace and, like other technologies, are often branded by carmakers. Honda, for example, uses the phrase Agile Handling Assist.

Some vehicles combine both differential- and brake-based torque vectoring. The Audi RS5, for example, offers a standard brake-based system while the differential, known in Audi lingo as the ‘quattro sport differential’, is optionally available.

Electric torque vectoring

Electric motors are able to respond instantly to inputs from an onboard computer or the driver, and are able to rapidly vary the amount of power and torque they produce. They offer the ideal foundation for the holy grail of torque vectoring – all-wheel torque vectoring.

As described in the video below of Rimac’s Concept One hypercar, this system involves a discrete electric motor being mounted to each wheel. This means that each wheel can be individually controlled.

Torque and power levels can be adjusted constantly, and can be combined with regenerative braking to precisely control the distribution of power across all four motors during both acceleration and braking.

The flexibility of this system also means much greater control over vehicle stability. At the push of a button, the driver can choose whether they would like their car to oversteer, understeer, or have a neutral handling balance.

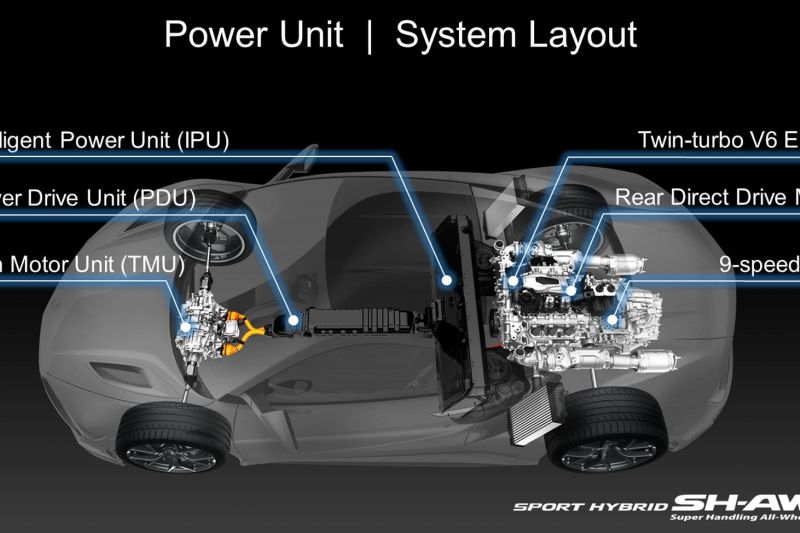

Rimac may not currently have a car on sale, but the Honda NSX is another vehicle that combines some of the advantages of electric torque vectoring with a more traditional differential-based setup.

Its Super Handling AWD (SH-AWD) system incorporates two electric motors (a Twin Motor Unit or TMU) to provide precise, flexible torque vectoring to the front wheels.

Meanwhile, the rear axle incorporates a mechanical LSD. A third electric motor acts as a ‘torque-fill’, channelling instant power and torque through the LSD (which distributes it between the rear wheels) whilst the larger turbocharged V6 engine spools up and takes over at higher speeds.

Whilst complex, the system overall offers a very high degree of flexibility as to how torque is distributed between the four wheels, enhancing handling.